Efficient logistics within port zones is crucial for the smooth operation of global supply chains. Drayage, the short-distance transportation of goods, plays a pivotal role in this ecosystem. Optimizing drayage operations not only enhances port throughput but also reduces costs and environmental impact. This article explores the importance of efficient logistics in ports, key optimization strategies, successful examples from industry leaders like YK Freight, and concludes with recommendations for effective drayage optimization.

Importance of Efficient Logistics in Ports

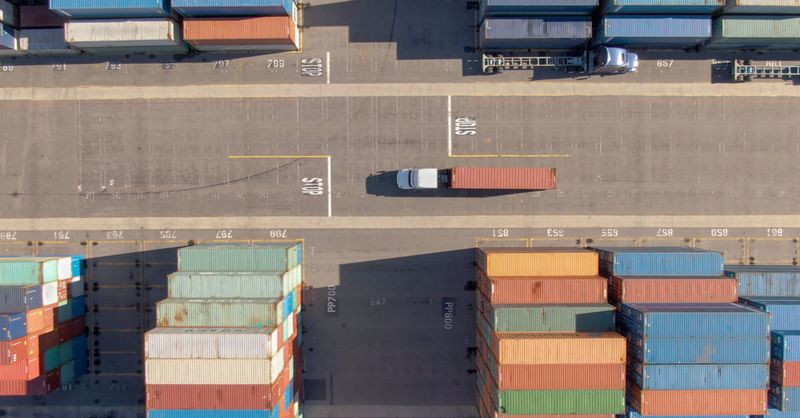

Ports are vital nodes in international trade, facilitating the movement of goods between countries and continents. Efficient logistics within port zones ensure that goods are transferred seamlessly between ships, trucks, and warehouses, minimizing delays and maximizing throughput. Drayage, which involves transporting containers over short distances, often between ports and nearby distribution centers or rail yards, is a critical component of this logistical chain.

Optimizing drayage operations is essential for several reasons:

- Cost Efficiency: Efficient drayage reduces transportation costs, which can be significant in the overall supply chain expenses.

- Time Savings: Streamlined operations reduce wait times and congestion, speeding up the movement of goods through ports.

- Environmental Impact: Efficient drayage can lower emissions per container moved, contributing to sustainability goals.

By focusing on optimizing drayage, ports can enhance their competitiveness, attract more shipping traffic, and support economic growth in their regions.

Key Optimization Strategies

Several strategies can significantly improve the efficiency of drayage operations within port zones. These strategies leverage technology, collaboration, and streamlined processes to achieve better outcomes.

Process Automation

Automation plays a crucial role in optimizing drayage operations. Technologies such as:

- Automated Scheduling Systems: These systems optimize routes and schedules based on real-time data, minimizing empty trips and maximizing truck utilization.

- Telematics and GPS Tracking: These technologies provide real-time visibility into truck locations and status, improving coordination and reducing waiting times.

- Electronic Data Interchange (EDI): EDI facilitates seamless communication between stakeholders, including shippers, carriers, and port authorities, reducing paperwork and administrative overhead.

Automation not only improves operational efficiency but also enhances data accuracy and compliance with regulatory requirements.

Collaboration with Port Authorities

Collaboration between drayage providers, shipping lines, and port authorities is crucial for optimizing operations. Key collaboration strategies include:

- Joint Planning and Coordination: Aligning schedules and operations to reduce bottlenecks and congestion.

- Infrastructure Investment: Developing infrastructure such as dedicated truck lanes and intermodal terminals to streamline drayage operations.

- Regulatory Alignment: Working together to comply with environmental regulations and improve sustainability practices.

Effective collaboration requires clear communication channels, shared goals, and a commitment to continuous improvement.

Examples of Successful Optimization by YK Freight

YK Freight, a leader in global logistics, has implemented several strategies to optimize drayage operations and improve efficiency within port zones.

Case Study: YK Freight's Optimization Initiatives

Automation Implementation

YK Freight invested in state-of-the-art automation technologies, including automated scheduling systems and GPS tracking. By integrating these technologies into their operations, YK Freight reduced truck idle time by 30% and improved on-time delivery rates by 15%.

Collaboration with Port Authorities

YK Freight worked closely with port authorities to optimize terminal operations. By aligning schedules and investing in dedicated truck lanes, they reduced average turnaround times by 20% and increased terminal throughput by 25% during peak hours.

Sustainability Initiatives

YK Freight implemented eco-friendly drayage practices, such as using low-emission vehicles and optimizing routes to reduce fuel consumption. These initiatives not only lowered operational costs but also aligned with global sustainability goals.

YK Freight's success demonstrates the effectiveness of integrating technology, collaboration, and sustainability into drayage optimization strategies.

Conclusion

Optimizing drayage operations in port zones is essential for enhancing logistical efficiency, reducing costs, and minimizing environmental impact. By adopting key strategies such as process automation and collaboration with port authorities, companies like YK Freight have achieved significant improvements in operational efficiency and customer satisfaction.

Recommendations for Optimization with YK Freight

Based on YK Freight's success and industry best practices, here are recommendations for optimizing drayage operations:

-

Invest in Automation: Implement automated scheduling systems and GPS tracking to improve operational efficiency and reduce idle times.

-

Collaborate Effectively: Foster partnerships with port authorities and other stakeholders to align operations, reduce congestion, and improve throughput.

-

Embrace Sustainability: Adopt eco-friendly practices, such as using low-emission vehicles and optimizing routes, to lower environmental impact and operational costs.

By following these recommendations, companies can optimize drayage operations within port zones, improve competitiveness, and contribute to sustainable global supply chains.

In conclusion, optimizing drayage operations requires a combination of technology, collaboration, and sustainable practices. By leveraging these strategies, companies can achieve significant improvements in efficiency, reduce costs, and support environmental stewardship in port logistics.

ASK YOUR QUESTIONS