Shipping large, heavy, or high-value items can be tricky, especially if you’re on a budget. Project cargo logistics is the solution for moving unusual or oversized shipments safely and efficiently. This guide explains what project cargo is, how it differs from regular shipping, and practical tips from YK Freight to save money while ensuring your vehicles or equipment arrive on time and in perfect condition.

Table of Content:

- What Is Project Cargo Logistics?

- How Is Project Cargo Different From Regular Shipping?

- Who Manages Project Cargo and What Do They Do?

- What Steps Are Involved in Planning Project Cargo?

- How Do You Choose the Right Transportation Strategy?

- How Does YK Freight Ensure Safety and Risk Management?

- Can Project Cargo Shipping Be Done on a Budget?

- Why Is Expert Coordination Important in Project Cargo Logistics?

What Is Project Cargo Logistics?

Project cargo logistics is a special type of shipping that focuses on moving large, heavy, valuable, or unusual items. Unlike regular shipments, which are usually straightforward—like sending a box or a small package—project cargo requires extra care, planning, and specialized equipment. It’s not just about transporting goods; it’s about handling items that are too big, too heavy, or too important to move in a standard way.

For example, imagine you just bought a salvage car at an online auction. Getting it from the seller to your repair shop might sound simple, but if the car is oversized, damaged, or needs special handling, regular delivery services may not be able to manage it. This is where project cargo logistics comes in. Companies like YK Freight arrange the right transport equipment, plan the best routes, and coordinate timing to make sure your car arrives safely and on schedule.

Another example could be transporting construction machinery or oversized vehicles. These shipments can’t fit into a standard truck or container, so project cargo logistics involves using specialized trailers, cranes, or multiple transport modes to move them efficiently.

How Is Project Cargo Different From Regular Shipping?

Project cargo differs from regular shipping in several important ways. Standard freight usually involves moving common items—like boxes, pallets, or small vehicles—that fit into typical trucks, containers, or vans. The process is generally predictable, straightforward, and relatively low-risk.

Project cargo, on the other hand, deals with shipments that are unusual in size, weight, or value. These items often cannot be transported using standard methods. For example, oversized vehicles, heavy machinery, or high-value goods like parts for construction or oil and gas equipment require special handling, equipment, and careful planning.

Industries such as mining, construction, and oil and gas frequently deal with project cargo because their shipments are large, heavy, and sometimes require multiple transport modes. But this doesn’t mean project cargo is only for industrial businesses. For a budget-conscious buyer shipping a salvage car from an auction, the same principles apply. The car may be too wide, tall, or delicate to ship via a normal courier or standard auto transport. Project cargo logistics ensures it’s moved safely, on time, and without damage.

Other differences include complexity and planning requirements. Standard shipping usually follows predictable routes and schedules. Project cargo, however, may involve special permits, cranes for loading or unloading, route adjustments, or coordinating multiple carriers. Every detail matters, because mistakes can be costly—both financially and in terms of time.

Who Manages Project Cargo and What Do They Do?

Project cargo shipments are complex, and managing them requires a high level of expertise. That’s where project cargo forwarders come in—at YK Freight, these professionals are the experts who plan, organize, and oversee every step of a project cargo shipment. Their main goal is to make sure that even the most unusual or high-value cargo reaches its destination safely, on time, and without unnecessary costs.

A project cargo forwarder wears many hats. They need strong planning skills to organize routes, schedules, and equipment. They must also coordinate multiple parties involved in the shipment—vendors, suppliers, transport companies, and sometimes even local authorities for permits. Excellent communication is crucial, because every small detail matters when moving heavy, oversized, or delicate cargo.

For example, if you bought a salvage SUV at an online auction, YK Freight’s project cargo team might coordinate a flatbed truck to pick it up from the seller, arrange for a specialized trailer for highway transport, and then schedule a crane to safely unload it at the repair shop. Each step involves different teams and equipment, all synchronized to prevent delays or damage.

Another example could be moving construction equipment from a port to a remote location. A project cargo forwarder would plan which transport modes to use—like a combination of sea freight, trucks, and possibly rail—and connect all the involved vendors. They ensure that loading and unloading equipment is available, permits are in place, and the shipment stays on schedule.

What Steps Are Involved in Planning Project Cargo?

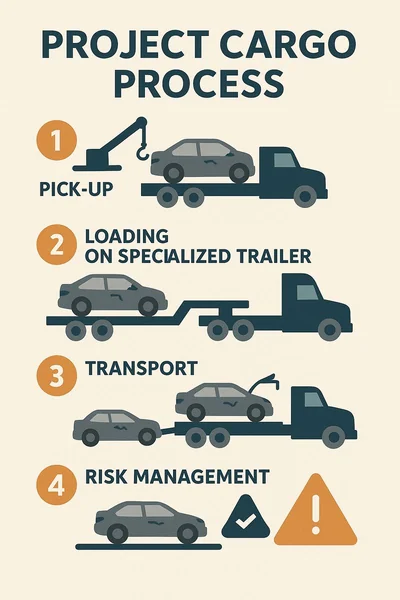

Planning is the heart of project cargo logistics. Without careful preparation, even a simple shipment of a high-value or oversized vehicle can run into delays, extra costs, or damage. At YK Freight, we follow a structured process to make sure every project cargo shipment goes smoothly, especially for budget-conscious customers who want to save money while ensuring safety.

The first step is securing capacity. This means making sure the right transport vehicles, trailers, and containers are available when needed. For example, if you bought a salvage SUV at an online auction, YK Freight ensures a flatbed truck or specialized trailer is ready to pick up your vehicle on the scheduled date—avoiding last-minute fees or delays.

Next is arranging handling equipment. Some cargo is too heavy or oversized for standard lifting or loading tools. Project cargo planning includes cranes, forklifts, or ramps, depending on the item. For instance, moving an oversized vehicle may require a trailer with a hydraulic lift to safely load and unload it.

Then comes scheduling shipments. Timing is crucial because project cargo often involves multiple steps or transport modes. Proper scheduling ensures the cargo moves efficiently from point A to point B without waiting too long at any stage. For your auction car, this could mean coordinating pick-up, transit, and delivery times so it arrives at the repair shop on schedule.

Finally, risk management is a key part of planning. Every project cargo shipment has potential risks: weather delays, traffic issues, or equipment problems. Planning ahead helps YK Freight anticipate challenges and implement backup plans. For example, if a flatbed truck isn’t available, a backup carrier is ready to step in, preventing costly delays.

Careful planning doesn’t just prevent problems—it saves money. By organizing transport efficiently, avoiding last-minute equipment rentals, and minimizing downtime, budget-conscious buyers can reduce shipping costs while keeping their vehicles safe.

How Do You Choose the Right Transportation Strategy?

Choosing the right transportation strategy is essential in project cargo logistics because the approach you take can affect cost, timing, and safety. At YK Freight, selecting the best strategy starts with understanding the type of cargo, its size and weight, and the delivery requirements. For budget-conscious customers, this means finding the most efficient way to ship vehicles or machinery without overspending.

One key consideration is multi-mode vs. single-mode transport. Multi-mode transport uses more than one method—for example, shipping a vehicle by sea to a port and then by truck to a repair shop. Single-mode transport relies on just one method, like a direct truck delivery. For oversized or fragile vehicles, multi-mode can often be more efficient and safer, while a direct route might be faster for smaller shipments.

Another factor is single vs. multiple shipments. Sometimes it’s better to consolidate multiple items into one shipment, which can lower costs per vehicle. For example, if a customer is shipping two auction cars from different sellers to the same repair shop, YK Freight may combine them on a single truck to save money. On the other hand, a very large vehicle may need its own dedicated shipment to ensure it fits safely and avoids damage.

Timing considerations are also important. Scheduling shipments to avoid peak traffic, high-season delays, or last-minute bookings can save both time and money. For instance, planning an auction car pick-up a few days in advance allows YK Freight to secure the right equipment at a better rate, instead of paying higher fees for urgent deliveries.

Finally, cost-effective choices for budget-conscious customers often involve careful route planning, selecting the right transport mode, and consolidating shipments when possible. YK Freight helps customers make these decisions, balancing speed, safety, and cost to deliver vehicles efficiently.

How Does YK Freight Ensure Safety and Risk Management?

Safety and risk management are at the core of project cargo logistics. At YK Freight, every shipment—whether it’s a high-value car, oversized vehicle, or machinery—is carefully planned to minimize risks, avoid delays, and prevent damage. For budget-conscious customers, this means you can ship your vehicle confidently without paying extra for mistakes or accidents.

One key technique is contingency planning. YK Freight identifies potential challenges before the shipment even begins, such as traffic delays, equipment failures, or weather disruptions. For example, if a flatbed truck transporting a salvage car breaks down, a backup truck is already scheduled to continue the delivery, preventing costly delays.

Risk management also involves proper equipment and handling. Oversized or delicate vehicles require specialized trailers, cranes, or securing mechanisms to prevent damage during transit. By using the right equipment and trained personnel, YK Freight reduces the chance of scratches, dents, or mechanical issues.

Communication is another critical element. YK Freight maintains constant contact with drivers, carriers, and customers to monitor progress and address any issues in real-time. For example, if a shipment of a high-value car is delayed at a port, YK Freight can quickly coordinate with local authorities and the transport team to keep the delivery on track.

Finally, thorough documentation and insurance planning help protect the shipment in case of unforeseen incidents. This adds a layer of security for customers shipping vehicles or equipment, ensuring they are financially protected while keeping costs manageable.

Can Project Cargo Shipping Be Done on a Budget?

Many people assume that project cargo shipping is always expensive, but with careful planning and smart strategies, it can be done cost-effectively. At YK Freight, we help budget-conscious customers move large, heavy, or high-value items—like vehicles, machinery, or oversized shipments—without overspending.

One key way to save money is combining shipments. If you’re shipping multiple vehicles or pieces of equipment, consolidating them into a single transport can lower costs per item. For example, if you bought two salvage cars from different auctions, YK Freight can organize a single truck to pick up both vehicles, reducing fuel costs and transport fees.

Choosing the right route is another practical tip. Avoiding congested areas, high-toll roads, or busy shipping seasons can save time and money. YK Freight analyzes routes carefully to find the most efficient and cost-effective path for every shipment, helping customers avoid unnecessary expenses.

Using specialized services wisely is also important. While project cargo requires equipment like flatbeds, cranes, or secure trailers, YK Freight ensures these are used efficiently—only when needed—so you don’t pay for extra services that aren’t necessary. For example, a slightly smaller salvage vehicle may only need a standard trailer rather than a full specialized rig, saving money without compromising safety.

Finally, advanced planning itself reduces costs. Booking transport and equipment in advance prevents last-minute charges, ensures availability, and avoids delays that could result in extra storage or handling fees.

Why Is Expert Coordination Important in Project Cargo Logistics?

Expert coordination is what makes project cargo logistics successful. Moving large, heavy, or high-value items involves many steps, multiple transport modes, and several parties. Without experienced professionals managing the process, shipments can face delays, damage, or unexpected costs.

At YK Freight, our team of project cargo experts ensures that every detail is handled correctly. From planning the route to arranging specialized equipment and coordinating with vendors, every step is carefully monitored. This level of coordination keeps shipments on schedule and reduces the risk of mistakes that can be costly for customers.

For example, transporting a salvage car from an auction may require a flatbed truck, a secure trailer, and coordination with the seller and repair shop. YK Freight ensures all parties are aligned—confirming pick-up times, transport equipment availability, and delivery schedules—so the vehicle arrives safely and on time.

Expert coordination also helps control costs. By anticipating challenges, combining shipments when possible, and selecting the most efficient transport modes, YK Freight keeps shipping expenses manageable for budget-conscious customers.

Further Reading

What Is Breakbulk Shipping? A Simple Guide for Moving Oversized Cargo

What Types of Freight Carriers Are in Logistics? A Simple Guide for Shippers

What is an Intermodal Carrier?

What is Drayage Trucking?

ASK YOUR QUESTIONS