In this guide, we’ll explain the transloading process—what it is, how it works, and why it's important for shipping goods efficiently. Transloading offers a cost-effective solution for moving cargo between different transportation modes, making it an ideal choice for businesses looking to save money and time. Whether you're shipping cars, machinery, or other goods, understanding transloading can help you optimize your logistics operations. Let's dive in!

What is Transloading?

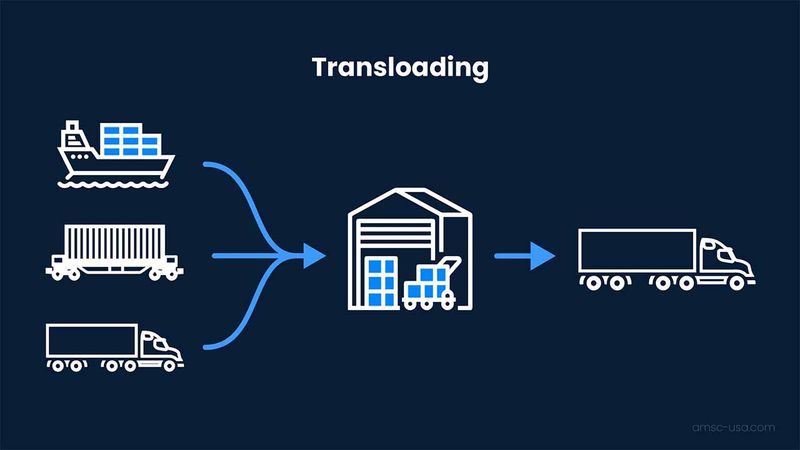

Transloading is a logistics process where goods are transferred from one mode of transportation to another during their journey from origin to destination. This process is common when freight is moved between different types of carriers, such as from ships to trucks or from trains to containers, ensuring that shipments continue their journey smoothly and efficiently. In recent years, transloading has become a standard practice in logistics due to the growth of e-commerce and international trade. Many manufacturers and retailers ship globally, and transloading helps solve these complex supply chain challenges.

In simpler terms, imagine you’re shipping a car from the U.S. to another country. The vehicle might be moved by ship across the ocean but needs to be transferred onto a truck for delivery to the final destination. This transition, moving goods from one transport mode to another, is what we call transloading. Most cargo worldwide is transported in rectangular steel containers, usually 20 or 40 feet long. These intermodal containers can be moved between trucks, trains, and ships without unloading, which has greatly increased the efficiency of transloading. For perishable products such as seafood or pharmaceuticals, specialized delivery methods are often used — like refrigerated trucks or air freight — to shorten transit times.

Benefits of Transloading

Transloading provides a wide range of benefits that make it an attractive option for businesses seeking to optimize their logistics. By combining multiple modes of transportation, companies can save costs, increase flexibility, reduce delivery times, and improve overall supply chain efficiency.

1. Cost Savings

One of the primary advantages of transloading is the potential for significant cost savings. By switching between transportation methods, businesses can select the most economical option for each leg of the journey. Long-distance shipping by rail or sea is usually cheaper than trucking, while trucks are ideal for last-mile delivery.

How it works: Goods are transloaded from ships to trains or trucks at specialized facilities, allowing companies to minimize costs while maintaining reliable service.

Example: A small business importing electronics from Asia ships by ocean freight to a U.S. port, then transloads the cargo onto trucks for nationwide distribution. This multimodal approach is far more affordable than trucking alone.

2. Flexibility

Transloading offers a high level of flexibility in choosing transport modes and routes. Companies can adapt to cost, availability, or disruptions by easily switching carriers at transloading hubs.

Example: If rail transport is delayed due to weather, a shipment of perishable food can be quickly transloaded onto trucks, ensuring timely delivery and avoiding losses.

3. Reduced Transit Times

By breaking shipments into segments and using the most efficient transport method for each, transloading often shortens overall delivery times.

Example: Instead of leaving goods on a slower ship or railcar for the entire journey, cargo can be offloaded at a major hub and moved by truck for faster final delivery.

4. Increased Reach

Transloading extends the reach of logistics operations, enabling delivery to locations not directly served by a single transportation mode. Companies without direct access to rail can still leverage rail networks through specialized terminals.

Example: A manufacturer may ship cargo by rail to a terminal, then transload to trucks for regional distribution, eliminating the need for costly investment in rail facilities.

5. Improved Safety and Security

The transloading process allows for careful inspection and handling of goods at transfer points, reducing risks of damage or loss. Sensitive cargo such as vehicles, electronics, or pharmaceuticals benefits from controlled environments and secure handling during transfers.

6. Handling Freight of Different Sizes

Transloading supports shipments of all sizes — from small LTL (less-than-truckload) cargo to oversized machinery. Facilities use specialized equipment like cranes, forklifts, pumps, or conveyors depending on cargo type.

Example: Construction materials like steel beams can be transloaded from ocean containers to flatbed trucks in smaller, manageable loads, lowering transport costs.

7. Optimized Supply Chain Efficiency

Transloading hubs act as strategic points in the logistics network, ensuring goods keep moving without unnecessary delays. This improves coordination, reduces idle time, and enhances overall supply chain performance.

8. Better Control and Monitoring

By passing through specialized facilities, shipments can be tracked more closely. Real-time monitoring, GPS, and IoT systems provide visibility and reduce risks of mishandling or delays.

Example: A retail company can monitor goods at each stage of transloading, adjusting delivery schedules or rerouting shipments when necessary.

How Does the Transloading Process Work?

Transloading is a multi-step process that involves the transfer of goods from one mode of transportation to another during their journey. The process is designed to ensure that freight moves smoothly, efficiently, and cost-effectively, even when switching between different types of carriers (e.g., ships, trucks, or trains). Transloading can be organized in different ways depending on whether rail or port facilities are available at the origin or destination. A common scenario is loading goods onto a truck, moving them to a terminal, transferring them to a train or another truck, and then reloading to a final truck for last-mile delivery. Here's a breakdown of the key stages involved in transloading:

1. Receiving the Cargo

The first stage of the transloading process begins when goods are delivered to a transloading facility. This facility acts as the staging area where cargo is received after being transported by its initial mode of transport. Depending on the type of freight, this could be a port, rail terminal, or warehouse.

For example, if a vehicle is being shipped overseas from the U.S., it might arrive at a port in a shipping container. Once the container is unloaded from the ship, the transloading process begins.

2. Inspection and Handling

Once the cargo arrives at the transloading facility, the next step is to inspect and handle the goods. This stage ensures that all items are accounted for and have not been damaged during their previous journey. For sensitive or high-value goods, such as cars or electronics, extra care is taken to verify their condition and secure them for the next stage.

During this step, some goods may be repackaged, labeled, or sorted based on their final destination. For instance, vehicles might undergo a quick inspection to check for any shipping-related damages, and they may be moved to a different storage area based on the next transport method.

3. Repositioning Cargo to the Next Mode of Transport

Once the cargo is inspected and prepared, the next stage of the process is to transfer it to the next transportation mode. This step is where the actual transloading happens, and goods are moved from one carrier to another, whether it’s from a ship to a truck, or from a railcar to a container.

For example, if a car is shipped by rail to a transloading hub, it will be offloaded from the train and moved to a truck for the final leg of its journey to a customer. The transfer can take place at a large transloading facility, where specialized equipment, such as cranes, forklifts, or conveyors, is used to safely load the cargo onto the new transport mode.

4. Staging for Final Delivery

After the goods have been transferred to the next transport mode, they are staged in an appropriate area for the final delivery process. This could involve moving the cargo to another warehouse or staging yard where it will await transportation to its destination. The staging process ensures that the goods are prepared and ready for their final leg of the journey.

For example, after a vehicle is offloaded from a rail car and loaded onto a truck, the truck may be parked at a staging area, waiting for the right time to continue its journey to the final destination. In some cases, additional paperwork, permits, or customs clearance may be required before the cargo is dispatched.

5. Final Delivery to the Destination

The final stage of the transloading process is the delivery of the cargo to its end destination. Whether it’s the customer, a retail location, or a distribution center, the goods are transported to their final stop.

If the goods were initially moved by rail, they are now transported by truck for local delivery. For international shipments, this stage could involve the cargo being transferred from a port to a warehouse for customs clearance and eventual delivery to the final customer.

6. Tracking and Documentation

Throughout the transloading process, tracking and documentation play a crucial role. Each step of the journey is tracked using logistics management systems, ensuring visibility and transparency throughout the shipping process. This tracking helps all parties involved stay updated on the location of the cargo, the status of the transfer, and any potential delays or issues.

Additionally, documentation, such as shipping receipts, invoices, and customs paperwork, is processed and updated at each stage to ensure that everything is in order and that the cargo is delivered without any legal or regulatory hiccups.

Challenges in Transloading Operations

While transloading offers many advantages, it also comes with challenges that businesses must manage carefully. These challenges can affect efficiency, costs, and the overall reliability of the supply chain.

1. Risk of Damage to Goods

One of the most significant challenges of transloading is the increased handling of cargo. Every time goods are transferred from one mode of transport to another, there is a chance of damage due to improper handling, equipment failure, or environmental factors.

Example: Fragile goods like electronics or glassware may suffer damage during loading and unloading if not handled with care.

2. Delays During Transfer

Transloading involves coordination between multiple carriers and facilities. If schedules are not perfectly aligned, delays can occur at transfer points. These delays can increase overall transit times and lead to missed delivery deadlines.

Example: A shipment arriving late at a rail terminal may be held until the next available truck is ready, adding days to the delivery schedule.

3. Higher Costs from Inefficiency

Although transloading often reduces costs overall, inefficiencies at transfer hubs can increase expenses. Delays, poor coordination, or lack of proper equipment may cause storage fees, demurrage charges, or higher labor costs.

Example: If cargo is held too long at a port due to miscommunication, the shipper may face costly detention fees.

4. Complexity in Coordination

Managing transloading requires precise coordination between carriers, logistics providers, customs officials, and warehouses. Without effective communication and planning, errors such as misrouting, misplaced shipments, or compliance issues can occur.

Example: A miscommunication between a shipping line and a trucking company can result in containers being sent to the wrong distribution center.

5. Limited Facility Availability

Not every location has a nearby transloading facility equipped to handle all types of cargo. In some regions, businesses may have to transport goods long distances just to reach a transloading hub, which adds time and cost.

6. Regulatory and Documentation Challenges

When transloading across international borders, compliance with customs regulations becomes critical. Incorrect paperwork or delays in customs clearance can stall shipments and cause penalties.

Benefits of Transloading Freight

Transloading freight offers a range of significant benefits that make it an attractive option for businesses looking to optimize their logistics. From reducing shipping costs to improving flexibility and speeding up transit times, transloading is an essential tool for many companies. Here's a closer look at the key benefits of using transloading in freight transport.

1. Cost Savings

One of the primary advantages of transloading is the potential for significant cost savings. By combining different modes of transportation—such as rail, sea, and truck—companies can choose the most cost-effective route for their shipments.

How it works:

Long-distance shipping, particularly by rail or sea, is often cheaper than transporting goods by truck alone. When goods are transloaded from one mode to another at a transloading facility, businesses can reduce transportation costs by taking advantage of lower-cost options for long-haul transportation (like rail) while using trucks only for the more expensive last-mile delivery.

Example: A small business importing electronics from Asia may first ship their goods by ocean freight, which is more affordable for long-distance travel. Once the goods arrive at a U.S. port, they can be transloaded onto a truck for distribution across the country. This combination of transport methods allows the business to save money compared to using just one mode for the entire journey.

2. Increased Flexibility

Transloading offers greater flexibility in choosing how and when shipments are moved, which is especially important when dealing with unpredictable conditions like weather delays, transportation bottlenecks, or last-minute orders.

How it works:

When goods are transloaded at a strategic location, businesses can switch to different modes of transport depending on the circumstances, giving them more options for responding to delays or changes in demand. For example, if there’s a delay in rail transport, goods can be switched to trucks to keep the shipment moving without having to wait for a specific rail car to become available.

Example: A company shipping perishable items might face unexpected delays in rail transport due to bad weather. By transloading the goods to trucks, the company can ensure that the items are delivered on time, preventing potential losses or spoilage.

3. Reduced Transit Times

Transloading can also help reduce the overall transit time of shipments. By efficiently switching from one mode of transport to another, businesses can streamline the journey and bypass unnecessary delays.

How it works:

When shipments are optimized through transloading, goods can be routed along the fastest paths. For instance, while long-distance transport may be slow, the transloading process allows goods to move quickly between transport hubs, allowing for a quicker final delivery. The flexibility to choose different transport options can also shorten the time needed for the entire shipment to reach its destination.

Example: A logistics company may choose to use transloading for a shipment moving from Asia to the U.S. Instead of relying solely on ocean freight, which might take weeks, goods can be quickly offloaded from ships and moved to trains or trucks for faster delivery to inland distribution centers.

4. Handling Freight of Different Sizes

Transloading can also help companies move freight of varying sizes more efficiently. This is particularly beneficial when dealing with cargo that may be too large or heavy for one type of transportation but can be broken down into smaller parts for easier handling.

How it works:

Transloading allows businesses to split up large shipments, which may otherwise incur higher fees due to the need for specialized transport. This helps reduce costs while still ensuring that large shipments reach their destination in manageable portions.

Example: A company shipping construction materials like steel beams might use transloading to offload large containers at a port and divide them into smaller, more easily transportable loads for rail or truck transport. This ensures that large freight gets where it needs to go without additional cost or damage.

5. Improved Supply Chain Efficiency

By optimizing the flow of goods from one mode of transport to another, transloading helps improve the overall efficiency of the supply chain. It ensures that shipments are always moving and allows businesses to manage their goods more effectively through better coordination between different transport providers.

How it works:

Transloading hubs act as critical touchpoints where goods are efficiently transferred between various modes of transport. These hubs streamline operations, eliminate the need for excessive handling, and reduce waiting times, making the entire supply chain smoother.

Example: A company that manufactures goods in the Midwest and ships them globally can use transloading at key port locations to streamline its supply chain. The company’s products can be unloaded from ships and quickly transferred onto trucks or trains, cutting down on waiting time and improving the speed of product delivery.

6. Better Control and Monitoring

Transloading provides businesses with better control over their shipments. Since goods pass through specialized facilities during transloading, companies have the opportunity to monitor the cargo more closely, ensuring that all items are intact, properly handled, and ready for the next stage of transportation.

How it works:

With the right systems in place, transloading facilities can offer real-time tracking of freight, providing valuable information about the status of the cargo and any potential issues. This added layer of control can lead to fewer delays, improved safety, and more accurate delivery estimates.

Example: A retail company using transloading for shipping products across the country can monitor their goods at each stage of transport. This allows them to make adjustments or take corrective actions if needed, such as rerouting shipments to avoid delays.

Challenges in Transloading Operations: Risk of Damage and Delays

While transloading offers significant benefits, it also comes with its share of challenges, particularly the risks of damage and delays. These factors can affect the overall efficiency and cost-effectiveness of the process. Transloading also comes with drawbacks: there is a risk of cargo damage or theft, as well as temporary loss of visibility in inventory management. These risks can be reduced by choosing a reliable provider and proper insurance, but they cannot be eliminated entirely. Let’s break down these challenges and how they can impact logistics operations.

1. Risk of Damage During Transfer

One of the most prominent challenges in transloading is the risk of damage when goods are transferred from one mode of transport to another. Each time cargo is unloaded, handled, and reloaded, there is an opportunity for items to be mishandled, dropped, or subjected to conditions that can cause harm. Even with the best equipment and handling practices, human error, or unforeseen circumstances, such as improper stacking or shifting, can lead to damage.

How it happens:

Goods are typically offloaded from one container and transferred to another—whether it’s from a ship to a truck, from a truck to a railcar, or vice versa. The movement of heavy or delicate cargo between different vehicles and warehouses can lead to accidental breakage, crushing, or exposure to environmental factors like extreme temperatures or moisture.

Example: A company transporting electronic goods might experience issues when their fragile equipment is offloaded from a ship and onto a truck. If the equipment is not properly secured during the transloading process, items could be damaged by sudden movements or rough handling, leading to product losses.

2. Handling Different Types of Cargo

Transloading often involves moving different types of cargo that may require specific handling procedures. For example, perishable goods like food or medicine need to be handled with care to maintain temperature, while heavy machinery or large items require specialized equipment. The challenge comes when goods of different shapes, sizes, or types are transferred at the same facility, increasing the chances of accidents or delays.

How it happens:

Not all types of cargo are suited for the same type of transloading equipment. The facilities may lack the necessary tools or expertise to handle certain shipments properly, resulting in damage or delays. For example, transporting a sensitive temperature-controlled shipment in the same facility as construction materials could cause damage due to improper handling or miscommunication about the type of care each product requires.

Example: A logistics company may have difficulty transloading medical supplies, which require precise temperature control, alongside construction materials that don't have such stringent requirements. If the proper precautions aren’t taken, the medical supplies might be exposed to temperature fluctuations, damaging the products and rendering them useless.

3. Delays in the Transfer Process

Another key challenge in transloading operations is the potential for delays. Since goods often have to be offloaded, stored temporarily, and reloaded, it can take longer than direct transportation between two points. Delays can occur for various reasons, including congestion at transloading facilities, inefficient processes, or poor coordination between transport modes.

How it happens:

When goods arrive at a transloading facility, there could be long wait times before they are offloaded or loaded onto the next mode of transport. These delays might be caused by bottlenecks in the process, such as a shortage of workers or equipment, or external factors such as weather, customs delays, or supply chain disruptions. These delays affect delivery times and may impact customer satisfaction.

Example: A company shipping goods from a U.S. port to a domestic warehouse may face delays at a transloading hub due to high demand. If too many shipments are arriving at once, there may not be enough space or personnel to move goods quickly, leading to a delay in final delivery.

4. Coordination and Communication Issues

Transloading requires seamless coordination between various parties involved in the supply chain—transport carriers, port authorities, warehouse workers, and logistics companies. A lack of clear communication between these groups can lead to misunderstandings, errors, and delays.

How it happens:

Without proper communication and systems in place, transloading operations may suffer from miscommunication regarding shipment status, timing, or destination. This can lead to goods being misplaced, loading onto the wrong vehicle, or failing to meet time-sensitive deadlines.

Example: A trucking company might arrive at a transloading facility to pick up goods but may be delayed because the port staff wasn't informed about the truck’s arrival time. As a result, the truck might have to wait for hours before the shipment is ready, causing a delay in reaching its destination.

5. Increased Costs Due to Delays

While transloading can save money in the long run, delays in the process can increase costs. Delays lead to extended transit times, more labor hours for handling, and potentially higher fuel costs if shipments are sitting idle longer than anticipated.

How it happens:

If cargo isn't transferred as scheduled, additional labor costs are incurred for handling, storage fees at transloading facilities, and more fuel is consumed in longer transport routes. The delays could also result in expedited shipping costs if businesses need to meet strict delivery deadlines.

Example: A business that depends on the timely delivery of goods may need to expedite its freight if a transloading operation takes longer than expected. This means additional costs for faster shipping, which could negate the savings that transloading would otherwise offer.

Key Differences Between Transloading, Cross-Docking, Intermodal Shipping, and Transshipment

In logistics, transloading is often confused with other related terms such as cross-docking, intermodal shipping, and transshipment. While all involve moving goods, they differ in purpose and process.

1. Transloading

Transloading is the transfer of goods from one mode of transport to another — for example, from a ship to a truck or from rail to a truck. It usually occurs when the original container or vehicle is not used for the entire journey.

Example: Goods arriving by ocean vessel are unloaded at a port and transferred into domestic trucks for final delivery.

2. Cross-Docking

Cross-docking involves transferring goods directly from an inbound truck or container to an outbound one with minimal or no storage in between. The goal is to reduce warehousing and speed up distribution.

Example: Retailers often use cross-docking to move products from suppliers directly to stores without holding them in warehouses.

3. Intermodal Shipping

Intermodal shipping refers to moving cargo in the same container using multiple modes of transport (e.g., ship → rail → truck). The key difference from transloading is that the cargo itself is not handled during mode changes — the entire container is moved as a unit.

Example: A container loaded in China might travel by ship to Los Angeles, then be moved onto rail for transport to Chicago, and finally onto a truck for local delivery, all without unloading the contents.

4. Transshipment

Transshipment occurs when goods are transferred from one vessel to another during their journey, typically at an intermediate port. Unlike transloading, which involves different modes, transshipment usually happens within the same mode (ship-to-ship).

Example: Containers shipped from India to the U.S. might first be transshipped in Dubai before continuing to their final destination.

Summary of Key Differences

- Transloading → Mode change (ship ↔ rail ↔ truck), cargo is physically handled.

- Cross-Docking → Direct transfer from inbound to outbound with no storage.

- Intermodal Shipping → Multiple modes, but the same sealed container is used.

- Transshipment → Cargo transferred between vessels of the same mode, usually at intermediate ports.

Best Practices for Optimizing Transloading

To maximize the benefits of transloading and minimize risks, companies should adopt proven best practices. These strategies help improve efficiency, reduce costs, and ensure smooth cargo handling.

1. Partner with Reliable Logistics Providers

Working with experienced logistics companies ensures that shipments are handled correctly at every transfer point. Reliable partners have established procedures, trained staff, and the necessary equipment to handle different types of cargo.

2. Use Technology for Visibility and Tracking

Implementing GPS tracking, IoT sensors, and cloud-based logistics platforms provides real-time visibility into shipments. This transparency allows businesses to monitor goods at every stage, identify potential delays, and take corrective actions.

3. Invest in Proper Packaging

Since transloading involves multiple handling stages, proper packaging is critical to prevent damage. Using reinforced containers, pallets, or protective materials helps safeguard fragile or sensitive items.

Example: Pharmaceutical shipments require insulated packaging and temperature control measures during transloading to maintain product integrity.

4. Ensure Strong Communication and Coordination

Effective communication between all parties — carriers, warehouse staff, customs brokers, and shippers — reduces the risk of misrouting or delays. Establishing a clear communication protocol helps ensure shipments move seamlessly.

5. Choose the Right Transloading Facilities

Not all facilities are equipped to handle every type of cargo. Selecting hubs with specialized equipment such as cranes, forklifts, pumps, or temperature-controlled storage improves efficiency and reduces risks.

6. Train Staff in Handling Procedures

Human error is a major source of damage during transloading. Providing regular training to staff on correct handling techniques, safety protocols, and compliance requirements ensures smoother operations.

7. Plan for Flexibility

Unforeseen disruptions such as port congestion, labor strikes, or weather conditions can delay shipments. Companies should have contingency plans to reroute cargo quickly and avoid extended downtime.

In conclusion, transloading is a valuable process that helps businesses save on shipping costs and improve efficiency by seamlessly moving cargo between different transportation modes. By understanding the ins and outs of transloading, you can make more informed decisions to optimize your logistics operations. Ready to take advantage of cost-effective shipping? Contact us at ykfreight.com today and start streamlining your shipping processes!

ASK YOUR QUESTIONS