Dry vans are among the most commonly used types of trailers in the trucking industry. They are versatile, efficient, and ideal for transporting a variety of goods. Understanding what a dry van is, how it works, and its significance in the supply chain is crucial for anyone involved in freight transportation. Whether you’re a business owner, a driver, or someone looking to learn more about the logistics industry, this guide will walk you through everything you need to know about dry vans and why they play such an important role in modern shipping.

What Is a Dry Van and What Is It Used For?

A dry van is a type of enclosed trailer used in freight transportation. It is one of the most common trailers on U.S. highways, designed to move non-perishable goods securely and efficiently. Unlike open trailers or flatbeds, dry vans are fully enclosed, offering protection from weather conditions and theft.

Most dry vans are made from steel or aluminum, featuring a rigid box design, a roof, and double rear doors for loading. The term “dry” means they are intended for freight that does not require refrigeration. Standard dimensions are typically 53 feet in length, though smaller versions exist.

Unlike straight trucks (box trucks), which combine cab and cargo on a single chassis for urban deliveries, dry vans are semi-trailers pulled by tractors. This gives them more space, higher payload capacity, and makes them the preferred choice for long-haul bulk loads, while straight trucks are better for last-mile city logistics.

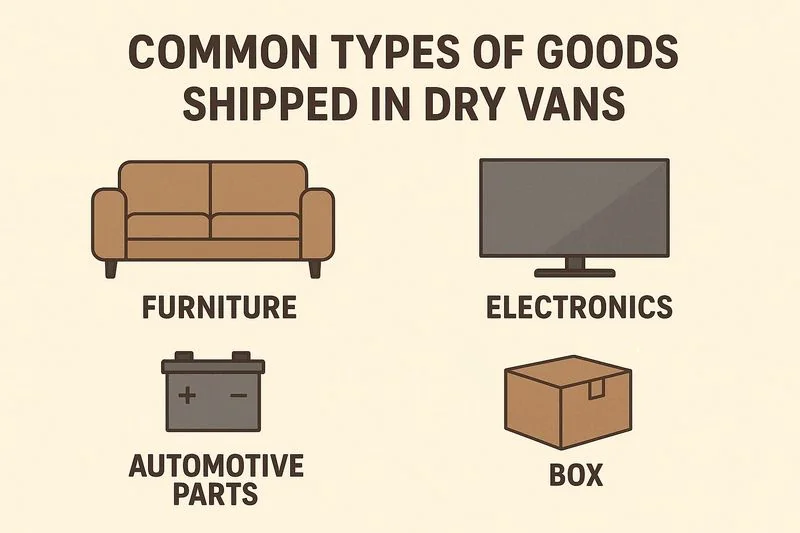

What Type of Freight Is Transported in Dry Vans?

Dry vans are used to transport a wide variety of non-perishable freight — cargo that doesn’t require refrigeration or special temperature control. Typical examples include:

- Packaged food and beverages (non-perishable)

- Clothing and textiles

- Furniture and household goods

- Electronics and appliances

- Automotive parts and equipment

- Paper products, office supplies, and packaging materials

- Pharmaceuticals and healthcare equipment

- E-commerce parcels and consumer goods

- Cleaning supplies and beauty products

- Agricultural products and building materials

In short, if cargo is boxed, palletized, and doesn’t require climate control, it is a good fit for a dry van. Dry vans are also heavily used in less-than-truckload (LTL) shipping, where smaller shipments are combined into one trailer, helping shippers save on costs while keeping goods safe from weather and theft.

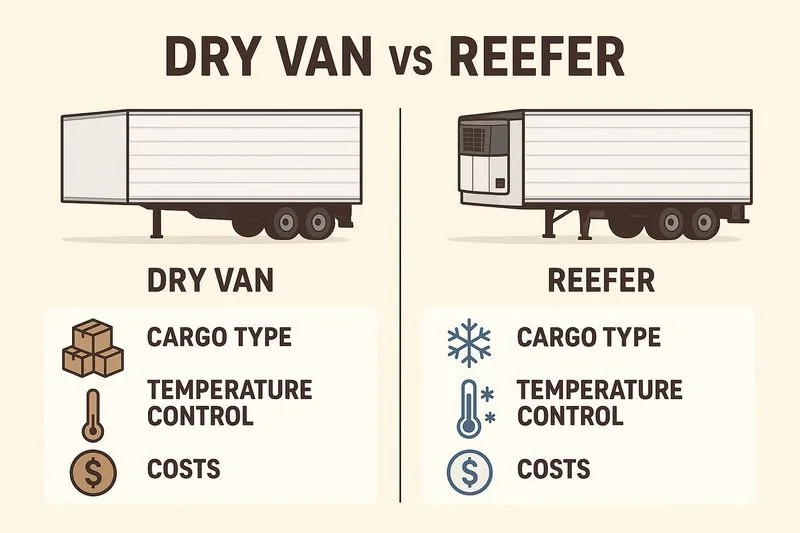

Dry Van vs. Reefer: Which One Is Better?

When comparing dry vans and reefer trailers, the right choice depends entirely on the type of freight you’re shipping.

Dry Vans

- Best for: general freight such as clothing, furniture, electronics, packaged goods, paper, auto parts.

- Advantages: versatile, widely available, budget-friendly, enclosed for protection from weather and theft.

- Limitations: no temperature control, cannot transport perishables, not suitable for oversized or overweight cargo, vulnerable to water damage if floors get wet.

Reefers (Refrigerated Trailers)

- Best for: perishable or temperature-sensitive goods such as fresh produce, meat, dairy, frozen foods, pharmaceuticals, or chemicals.

- Advantages: refrigeration unit ensures proper temperature throughout transit; essential for cold chain logistics.

- Limitations: higher operating costs, limited availability, more expensive shipping rates.

👉 One isn’t “better” than the other overall — it depends on the cargo.

- For non-perishable freight, a dry van is usually the best option due to lower cost and availability.

- For perishable or temperature-sensitive goods, a reefer is the only option.

Key Features of a Dry Van

Dry vans are designed to maximize cargo space while staying within U.S. road regulations. Their features make them the most practical and widely used trailers in trucking.

Standard Dimensions (53’ Dry Van):

- Interior length: ~53 ft (16.15 m)

- Interior width: 100–102 inches (2.54–2.59 m), usable width ~98–100 inches

- Interior height: 110–114 inches (2.79–2.90 m)

- Door opening: 94–98 inches wide, 104–110 inches high

- Cubic capacity: ~3,800–4,200 cubic feet (48’ trailers: 3,200–3,500 cubic feet)

Pallet Capacity:

- Standard 48" × 40" pallets: 26 pallets (13 rows of 2, straight load)

- With pinwheel loading and 102-inch width: up to 28 pallets

- 42" × 42" pallets: ~30 pallets

- Double stacking: possible if cargo is stackable and height allows

Weight and Payload:

- Empty dry van (tare): 10,000–15,000 lbs (4,500–6,800 kg)

- Tractor: 15,000–20,000 lbs (6,800–9,000 kg)

- Combined tare weight: 25,000–35,000 lbs (11,300–15,800 kg)

- Legal U.S. gross vehicle weight limit (GVWR): 80,000 lbs (36,287 kg)

- Practical payload capacity: 42,000–45,000 lbs (19,000–20,400 kg)

Limitations and Considerations:

- Length restriction: max 53 ft (oversized/overweight loads excluded)

- Flooring: many dry vans use wooden floors, which can be damaged by moisture or leaks

- Weight distribution: must be balanced to comply with axle limits

- GVWR of most dry vans: ~65,000–70,000 lbs, but combined truck + trailer + cargo must not exceed 80,000 lbs

Example:

A standard 53’ dry van can carry 26 standard pallets. If each pallet weighs ~1,700 lbs, the load totals ~44,200 lbs, which is within the safe range of most dry vans.

👉 Thanks to this balance of size, weight, and cubic capacity, dry vans remain the most versatile trailer type for shippers across industries.

How Much Does a Dry Van Trailer Weigh?

A dry van’s empty weight typically ranges between 10,000 and 15,000 pounds (4,500 to 6,800 kg), depending on its build, size, and the materials used by the manufacturer. This tare weight is important to consider because it directly affects how much cargo the trailer can legally carry.

How Much Do Dry Van Trailers Weigh When Loaded?

When fully loaded, the combined weight of the tractor, trailer, and freight cannot exceed 80,000 pounds (36,287 kg) under U.S. federal regulations. This legal limit ensures safe operation on highways and compliance with transportation laws.

In practice, this means that after accounting for the tractor and trailer weight, a standard dry van can typically haul around 42,000–45,000 pounds (19,000–20,400 kg) of freight.

This weight range is important to consider, as it affects the overall weight capacity of the trailer. When loaded, the total weight of the trailer and its contents cannot exceed the legal weight limit for road transportation, which is generally around 80,000 pounds in the United States. It’s essential to account for the weight of both the trailer and the cargo to ensure safe transport and compliance with legal requirements.

How much can a dry van haul?

A standard 53-foot dry van trailer is designed to carry a significant amount of freight, but weight limits are strictly regulated.

Typical Weight Breakdown:

- Empty dry van trailer: 10,000 – 15,000 lbs (4,500 – 6,800 kg)

- Tractor (semi truck): 15,000 – 20,000 lbs (6,800 – 9,000 kg)

- Combined tare weight: 25,000 – 35,000 lbs (11,300 – 15,800 kg)

- Maximum gross vehicle weight (U.S. legal limit): 80,000 lbs (36,287 kg)

- Maximum payload (freight capacity): generally 42,000 – 45,000 lbs (19,000 – 20,400 kg)

Limitations and Considerations:

- Length restriction: Standard dry vans are limited to 53 feet, which excludes oversized or exceptionally heavy freight.

- Trailer flooring: Many dry vans have wooden floors, which can be vulnerable to moisture damage or weakening if wet cargo leaks.

- GVWR: Most 53’ dry vans have a Gross Vehicle Weight Rating (GVWR) of 65,000–70,000 lbs, but the total combined weight of truck, trailer, and cargo must not exceed the federal 80,000 lb limit.

Practical Example:

A 53’ dry van can usually fit 26 standard 48" × 40" pallets. If each pallet weighs about 1,700 pounds, the total load would reach 44,200 pounds, which is right at the safe payload capacity for most dry vans.

Limitations include maximum load weight of 42,000–45,000 pounds and length restrictions of 53 feet, which can exclude heavy or oversized cargo. Wooden flooring inside many dry vans can be vulnerable to moisture damage, potentially causing mold or weakening if wet cargo leaks. The haul capacity is determined by the trailer's Gross Vehicle Weight Rating (GVWR), which is the maximum combined weight of the trailer and cargo it can carry safely. Most 53-foot dry vans have a GVWR of around 65,000 to 70,000 pounds. However, when fully loaded, the weight of the trailer itself, along with the load, should not exceed the standard 80,000-pound weight limit, including the weight of the truck towing the trailer.

In addition to the dimensions and weight, understanding the standard specifications of a dry van is essential for determining how much cargo it can carry.

How Many Cubic Feet in a Dry Van?

In addition to weight limits, understanding the storage capacity of a dry van is crucial for planning shipments. A standard 53-foot dry van provides about 3,800 to 4,200 cubic feet of usable space, depending on its exact interior dimensions. The average measurements are 53 feet in length, 98–102 inches in width, and 110–114 inches in height, which translates to roughly 4,000 cubic feet of capacity. A 48-foot dry van typically offers around 3,200 to 3,500 cubic feet.

Dry vans are designed with a flat floor and high roof, which helps maximize cargo space. This layout makes them suitable for stacking goods and using load straps to secure items during transit.

How Many Standard Pallets Fit in a Dry Van?

The number of pallets a dry van can carry depends on pallet size and loading method. Using the standard 48" × 40" GMA pallet, the capacity is:

- 53-foot dry van: typically 26 pallets arranged in 13 rows of 2. In some cases, it’s possible to fit 28 pallets if the trailer has a full 102-inch interior width and freight allows for pinwheel loading.

- 48-foot dry van: usually 24 pallets arranged in 12 rows of 2.

Most carriers and shippers use 26 pallets for a 53’ dry van and 24 pallets for a 48’ dry van as the standard benchmark.

Because of their versatility, dry vans can handle a wide variety of freight, from large goods to smaller packages, making them the most common trailer type for general cargo in the trucking industry.

This translates to about 26 standard-sized pallets (48" x 40"), depending on how efficiently the pallets are loaded. Dry vans are designed to maximize cargo space with a flat floor and high roof, making them suitable for stacking goods or using cargo strapping to secure items. Dry vans can accommodate a variety of freight, from large goods to smaller packages, making them a versatile choice for many shippers.

Who Works with Dry Vans?

Dry vans, being the most common trailer type in U.S. trucking, require skilled professionals to ensure safe and efficient transportation. The key role belongs to dry van drivers — licensed operators of tractor-trailers with enclosed van trailers.

Who They Are:

A dry van driver is a commercial truck driver who hauls non-perishable goods such as packaged food, clothing, electronics, furniture, paper products, and auto parts. Because dry van freight covers such a wide range of industries, these drivers make up one of the largest groups in the trucking workforce.

Typical Responsibilities:

- Picking up freight from warehouses, distribution centers, auctions, or factories

- Transporting loads over local, regional, or long-haul routes

- Loading, unloading, and securing cargo properly (often using straps, pallets, or seals)

- Ensuring the trailer is weather-proof, sealed, and maintained in good condition

- Following federal weight limits, DOT regulations, and road safety laws

- Delivering goods to consignees and handling required documentation

- Communicating with dispatchers and keeping trip paperwork in order

Why It Matters:

Dry van drivers are the backbone of the U.S. supply chain. They ensure a continuous flow of everyday products across the country, supporting retail, manufacturing, and e-commerce. Many drivers begin their careers with dry vans because this segment offers stable work, year-round demand, and a broad range of routes before moving into specialized trucking such as reefers, flatbeds, or tankers.

👉 In short, dry van drivers combine operational skills, regulatory compliance, and logistical coordination, making them essential for the functioning of the freight industry.

What Is a Dry Van CDL?

To legally operate a dry van, drivers in the U.S. must hold a Commercial Driver’s License (CDL). Since most dry vans are 53-foot tractor-trailers with a gross vehicle weight rating (GVWR) well over 26,001 lbs, a CDL ensures that drivers are properly trained for safe operation.

Type of CDL Needed:

- Class A CDL — required for dry van drivers, as they operate large combination vehicles (tractor + trailer).

- This license allows interstate driving and covers the majority of freight operations.

Training and Exams:

- Entry-Level Driver Training (ELDT): mandatory courses approved by the FMCSA.

- Written tests: covering road safety, federal regulations, and vehicle operation.

- Skills test: includes pre-trip inspection, backing maneuvers, and on-road driving.

- Medical exam: drivers must meet DOT physical requirements.

- In some cases, background checks are also required.

Endorsements:

- For standard dry van freight, no extra endorsements are needed.

- If hauling hazardous materials in a dry van, an H (Hazmat) endorsement is required.

Why It Matters:

A CDL is proof that a driver has the skills, knowledge, and legal clearance to operate heavy commercial vehicles. It ensures compliance with federal and state laws, reduces safety risks, and gives shippers confidence that their freight is in capable hands. Without a CDL, operating a dry van is illegal and subject to severe penalties.

👉 In essence, the CDL is the foundation of professional dry van trucking, opening the door for drivers to enter one of the largest and most stable segments of the freight industry.

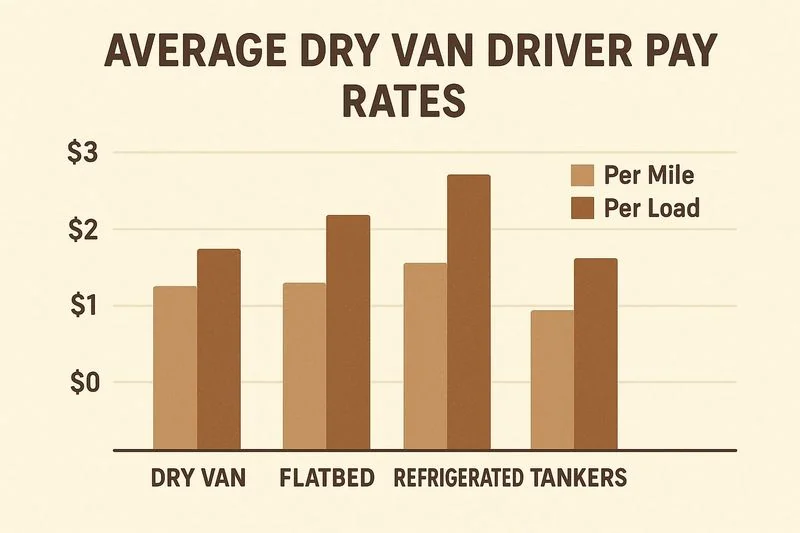

How Much Do Dry Van Loads Pay?

Dry van freight is the most common and steady segment of U.S. trucking, offering drivers consistent work, though typically at lower rates than specialized hauling (reefers, flatbeds, tankers). Earnings vary depending on experience, region, market demand, and whether the driver is a company employee or an owner-operator.

Average Rates (2024):

- Per mile (owner-operators): $1.50 – $2.50 (peaks may exceed $3.00 in high-demand regions)

- Per load (regional hauls): $600 – $1,500

- Per load (long-haul): $1,500 – $4,000+

- Annual (company drivers): $45,000 – $75,000 (experienced drivers can earn more with bonuses)

- Annual (owner-operators): $80,000 – $120,000+ depending on consistency and expenses

Pay Structures:

- By the mile: most common for long-haul drivers; earnings increase with distance but fluctuate with fuel prices and region.

- By the load: often used for regional or contracted hauls.

- Bonuses: many carriers provide safety, performance, and mileage-based incentives.

Comparison with Specialized Hauling:

- Dry van: steady demand, high availability of loads, lower entry barrier → but generally lower pay compared to niche freight.

- Reefer (refrigerated): higher rates due to temperature control, but more responsibility and equipment costs.

- Flatbed: also higher rates, requires specialized skills (oversized/heavy freight).

Summary:

On average, dry van drivers earn a stable income with predictable opportunities, making it one of the best starting points in trucking. While not the highest-paying niche, dry vans provide year-round consistency, steady freight, and opportunities for both company drivers and owner-operators.

👉 Many drivers begin with dry vans to build experience before moving into specialized, higher-paying segments.

ASK YOUR QUESTIONS