Shipping a car doesn’t have to be expensive or stressful. A smart supply chain strategy helps you plan ahead, avoid delays, and cut unnecessary costs. This guide explains simple, practical options for better management—like predictable planning, flexible routes, and clear communication—so budget-conscious buyers can save money and get their cars delivered on time, every time.

Table of Content:

- What Is a Supply Chain Strategy and Why Does It Matter for Car Shipping?

- How Does Supply Chain Strategy Help Reduce Shipping Costs?

- What Does Predictable Planning Mean in Real Shipping Situations?

- How Can Better Data and Forecasting Prevent Expensive Mistakes?

- Why Is Agility Important When Shipping Cars?

- How Does Supply Chain Resilience Protect You From Delays and Extra Costs?

- Why Should You Work With Multiple Carriers and Partners?

- What Does Supply Chain Integration Mean for Auto Shipping?

- How Does Better Communication Prevent Costly Shipping Problems?

- How Can Centralized Management Improve Control Over Shipping Costs?

- How Can Small Businesses and Individual Buyers Use These Strategies?

- How Does YK Freight Support Smarter Supply Chain Strategy?

What Is a Supply Chain Strategy and Why Does It Matter for Car Shipping?

A supply chain strategy is a simple plan for how a car moves from the seller to your driveway. It covers who picks up the vehicle, how it is transported, where it is stored, and how long each step takes. Instead of reacting to problems after they happen, a strategy helps you plan ahead.

For budget-conscious car buyers, this matters a lot. Many extra costs in car shipping come from poor planning. For example, if a carrier is not booked on time, you may have to pay rush fees. If paperwork is late, the car may sit at an auction yard or port, and you get charged storage. If routes are not planned well, the car can be sent the long way, adding time and fuel costs.

With a clear supply chain strategy, these problems are easier to avoid. You know when the car will be picked up. You know which carrier is responsible. You know what documents are needed and when. This reduces surprises and helps you control your budget.

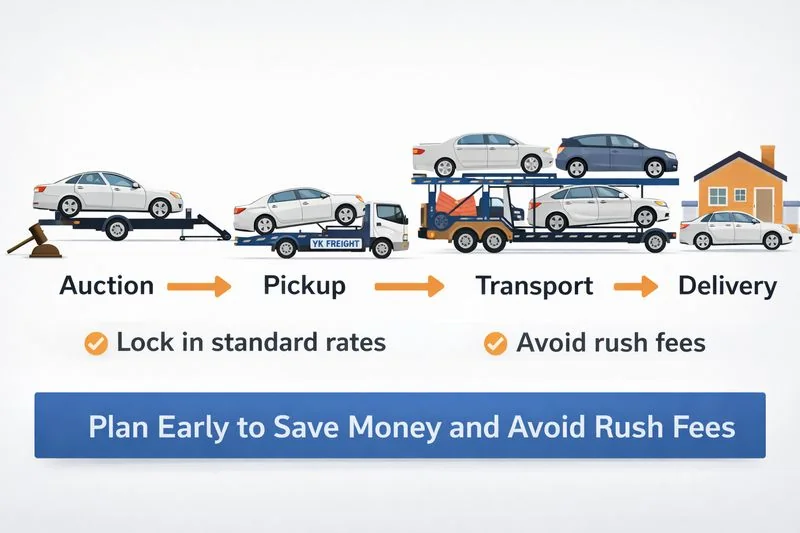

For example, imagine you buy a car at auction and wait a week before booking transport. Prices go up, and now you pay more just to move the car. With a strategy, transport is planned right after purchase. The pickup is scheduled early, and you lock in a better rate.

How Does Supply Chain Strategy Help Reduce Shipping Costs?

A good supply chain strategy is one of the most effective ways to lower your total car shipping costs. It helps you make smart decisions before problems appear, instead of paying extra to fix them later.

Planning is the first big money saver. When pickup and delivery are scheduled early, carriers can fit your car into normal routes. This is usually cheaper than last-minute or rush transport. For example, if you know your auction release date in advance and book transport right away, you avoid premium rates for urgent pickups.

Route selection also plays a major role. Not all routes cost the same. A smart strategy looks at distance, traffic, fuel costs, and carrier availability. Sometimes a slightly longer route with better carrier coverage is cheaper than a shorter route with limited options. Without a strategy, cars can be sent on inefficient routes that increase time and cost.

Working with the right partners is another key factor. Reliable carriers, ports, yards, and brokers help prevent delays and mistakes. Delays often mean storage fees, rebooking fees, or extra handling charges. A strong partner network helps move your car smoothly from one step to the next, reducing these hidden costs.

For budget buyers, this makes a real difference. Instead of paying for storage at the auction, you save by getting fast pickup. Instead of paying extra for re-routing, you save by choosing the best path from the start. Over time, these small savings add up to hundreds of dollars per vehicle.

What Does Predictable Planning Mean in Real Shipping Situations?

Predictable planning means using past experience and basic data to plan shipping before problems start. Instead of guessing or waiting until the last moment, you look at patterns and prepare for them. In car shipping, this can make a big difference in both price and timing.

For example, car auctions have busy seasons. During tax refund season, many buyers purchase vehicles at the same time. At the end of the year, dealers often clear inventory. During these periods, demand for carriers goes up, and so do prices. With predictable planning, you expect this and book transport earlier to lock in better rates.

Forecasting does not have to be complicated. It can be as simple as knowing when you usually buy cars, how long auction releases take, and how fast carriers fill up in your area. If you know that pickups in your state get delayed every winter due to weather, you can plan extra time and avoid paying for urgent transport later.

Predictable planning also helps avoid storage fees. When transport is arranged in advance, your car is picked up quickly after auction release. This reduces the risk of daily storage charges that can add up fast. Many budget buyers lose money not on shipping itself, but on waiting costs.

A real-life example: you buy a car on Friday and wait until Wednesday to book transport. By then, most carriers are full. The only option is a higher-priced pickup or paying storage while you wait. With predictable planning, transport is booked right away. The car is added to a normal route, and you pay less.

How Can Better Data and Forecasting Prevent Expensive Mistakes?

Better data and simple forecasting help you make smarter shipping decisions and avoid common, costly errors. Instead of relying on guesswork, you use real information from past shipments, auction activity, and market trends to plan ahead.

Shipping history is one of the most useful tools. If you regularly ship from the same auctions or states, you can see patterns. You may notice that certain locations always take longer to release vehicles. Others may have limited carrier availability. Knowing this in advance helps you book earlier and avoid paying for rush pickup later.

Auction trends also matter. When large auction events or seasonal sales happen, many buyers compete for the same carriers. Prices go up, and schedules fill fast. By tracking these trends, you can plan your purchases and shipping around peak times, or at least prepare for higher demand. This helps you avoid surprise price increases.

Market data, such as fuel prices and regional carrier availability, also affects routes and costs. In some cases, a direct route may be more expensive due to low carrier supply. A data-based strategy may suggest a nearby hub or a different path that is cheaper and faster overall. Without this insight, buyers often choose routes that look simple but cost more.

A common mistake is waiting too long and then paying for urgent delivery. With better data, you know when delays are likely. You book early, secure a standard rate, and avoid premium pricing. Another mistake is choosing inefficient routes because they seem shorter on a map. Data shows which routes actually move faster and cost less in real conditions.

Why Is Agility Important When Shipping Cars?

Agility in car shipping means being able to change plans quickly when something unexpected happens. In real life, shipping does not always go exactly as planned. Auctions can delay releases, ports can get congested, weather can slow down transport, and pickup locations can change. An agile supply chain helps you adjust without paying high extra costs.

For example, an auction may say a car will be ready on Monday, but the release is delayed until Thursday. If your transport plan is rigid, the carrier may cancel or charge a rebooking fee. With an agile approach, YK Freight can shift pickup dates, move the car to another route, or assign a different carrier without starting from zero.

Port congestion is another common issue. When ports are busy, trucks may wait longer, and schedules can change fast. An agile strategy allows you to reroute, use a different terminal, or reschedule delivery to avoid long delays and extra handling fees.

Weather is also a major factor. Snowstorms, heavy rain, or hurricanes can shut down routes or slow carriers. With flexibility built into the plan, your shipment can be delayed safely, rerouted, or reassigned before problems turn into expensive emergencies.

Changes in pickup locations also happen often. A car may be moved to a different yard, or a seller may update the release point. Without agility, this can mean extra miles and extra charges. With a flexible strategy, the new location is quickly added to the plan, and the best available carrier is selected.

How Does Supply Chain Resilience Protect You From Delays and Extra Costs?

Supply chain resilience means having backup options when things do not go as planned. Instead of relying on one carrier, one route, or one fixed schedule, a resilient setup gives you alternatives. This helps keep your car moving even when problems happen.

In car shipping, delays are common. A carrier can break down. A driver may cancel. A route may be closed due to an accident or bad weather. If you only have one option, your car may sit and wait. Waiting often means storage fees, missed delivery windows, and higher costs to fix the delay later.

With a resilient strategy, there are backup carriers ready to step in. If one route becomes slow or expensive, another route can be used. If a pickup is missed, another carrier can be assigned without restarting the whole process. This reduces downtime and keeps your shipment on track.

For example, if a carrier scheduled to pick up your car from an auction cancels at the last minute, a non-resilient plan means you wait days for a new option. With resilience, YK Freight can quickly assign a different carrier from its network. The car is picked up sooner, and you avoid storage charges and rush fees.

Resilience also protects you from sudden cost increases. If fuel prices spike or a region becomes overloaded, having alternative routes and partners helps find more affordable options. You are not forced to accept the first expensive solution.

Why Should You Work With Multiple Carriers and Partners?

Relying on just one carrier or one partner is risky in car shipping. If that single option becomes unavailable, raises prices, or runs into delays, your entire shipment can be affected. When you have no alternatives, you often end up waiting or paying more to fix the problem.

Working with multiple carriers and partners gives you flexibility and choice. If one carrier is fully booked, another may have space. If one route is slow, another partner may offer a faster or cheaper path. This helps you avoid bottlenecks where cars get stuck waiting for one overloaded provider.

Multiple partners also help with pricing. When there is more than one option, you can choose the most cost-effective solution instead of accepting whatever price one carrier offers. This is especially important during busy seasons, when some carriers raise rates due to high demand.

Speed is another benefit. If a pickup needs to happen quickly, having access to a wider network means a better chance of finding a nearby truck. This reduces waiting time and lowers the risk of storage fees at auctions or yards.

For example, if a single carrier that usually handles your route is delayed, your car could sit for days. With multiple partners, YK Freight can switch to another carrier in the same area. The pickup still happens, and you avoid extra charges and long delays.

What Does Supply Chain Integration Mean for Auto Shipping?

Supply chain integration means that everyone involved in moving your car is connected and sharing information. This includes the auction, the carrier, the port or storage yard, and the final delivery location. Instead of each part working separately, integration helps all sides stay on the same page.

When systems and communication are connected, fewer mistakes happen. For example, if the auction updates the release date, that information is shared right away with the carrier. This prevents missed pickups and wasted trips, which often lead to extra fees and delays.

Integration also reduces waiting time. If paperwork, titles, or release forms are visible to all parties, the car can be picked up as soon as it is ready. Without integration, one side may be waiting for documents that another side already has. This causes unnecessary delays and can lead to storage charges.

Paperwork is another common problem area. In auto shipping, small errors in names, VIN numbers, or locations can stop a shipment. With integrated systems and clear communication, these issues are caught early. Fixing them before pickup is much cheaper than fixing them after a truck arrives.

How Does Better Communication Prevent Costly Shipping Problems?

Better communication is one of the simplest ways to prevent expensive mistakes in car shipping. When everyone involved—auction staff, carriers, ports, and delivery teams—shares information in real time, problems like missed pickups, wrong addresses, or duplicate fees are much less likely to happen.

For example, imagine a buyer purchases a car at an auction but the carrier isn’t informed of the updated pickup time. Without clear communication, the truck may arrive on the wrong day. The result? The car sits at the yard, storage fees start accumulating, and the buyer may need to pay a rush fee to reschedule.

Clear communication also prevents address errors. Cars are often shipped long distances, and even a small mistake in the delivery address can cause the truck to take the wrong route. This not only adds fuel costs but also delays the final delivery. Shared systems allow all parties to see the correct address and update it instantly if something changes.

Duplicate fees are another common issue. Without coordinated updates, multiple carriers may attempt the same pickup, or multiple offices may process the same paperwork, causing unnecessary charges. With a shared communication system, everyone knows what has already been completed, avoiding these mistakes entirely.

How Can Centralized Management Improve Control Over Shipping Costs?

Centralized management means organizing all parts of your car shipping process in one place. Instead of dealing with multiple contacts, invoices, schedules, and updates spread across different carriers, ports, and auctions, everything is tracked together. This makes it easier to see where money is going, how long shipments take, and where problems occur.

For budget-conscious buyers, this level of control is essential. When all information is in one system, you can track spending on each shipment and spot unnecessary costs. For example, if storage fees are creeping up at a particular auction yard, centralized management makes it clear where delays happen so you can address them before they become expensive.

Centralized management also helps monitor timelines. You can see if a pickup or delivery is running behind schedule and take immediate action—such as contacting the carrier, rerouting, or rescheduling—to avoid rush fees or additional handling charges. This proactive approach prevents small delays from turning into costly mistakes.

Performance tracking is another major advantage. You can evaluate carriers, routes, and partners based on reliability, speed, and cost. If one carrier consistently causes delays or extra fees, you can switch to a more efficient option next time. This continuous improvement reduces waste and helps you get the most value out of every shipment.

How Can Small Businesses and Individual Buyers Use These Strategies?

Even if you’re a small business or an individual buyer shipping just one car at a time, supply chain strategies can make a big difference. You don’t need a huge budget or complicated systems—simple steps can save money, reduce delays, and make shipping more predictable.

The first step is planning ahead. As soon as you know when a car will be ready, schedule transport. Early bookings give you access to standard rates, reduce storage fees at auctions or ports, and prevent the need for rush shipping. Even a small delay in planning can lead to higher costs, so a little foresight goes a long way.

Next, focus on flexibility. Choose carriers and partners who can adapt to changes in pickup times, weather, or location. If your car is delayed or moved, a flexible plan allows you to adjust without paying extra. You don’t need multiple carriers yourself—working with a provider like YK Freight gives you access to a network of partners and routes, so you benefit from agility without managing everything on your own.

Communication is key for small shippers too. Make sure your auction, carrier, and delivery team can share updates quickly. Even simple tools like email notifications, online tracking, or a single point of contact help avoid missed pickups, duplicate fees, or delivery errors.

Finally, track your spending and performance. Keep a record of shipping costs, timelines, and any unexpected fees. Over time, you’ll see patterns—such as certain carriers being more reliable or certain auction periods being busier—and you can adjust your plans to avoid mistakes and save money in the future.

How Does YK Freight Support Smarter Supply Chain Strategy?

YK Freight helps car buyers apply smart supply chain strategies without the stress of managing every detail themselves. From planning to delivery, YK Freight provides tools and services that save money, reduce delays, and make the entire shipping process smoother.

Planning is easier with YK Freight. As soon as you purchase a car at auction, YK Freight helps schedule pickup and delivery. By coordinating early, you lock in standard rates and avoid rush fees. Their team can forecast busy periods, like high-demand auction seasons, and advise on the best times and options for shipping your car.

Flexibility is built into every shipment. Life is unpredictable—auctions get delayed, weather changes, and routes can shift. YK Freight works with multiple carriers and partners, so if one option isn’t available, they quickly find an alternative. This agility prevents extra storage fees, rebooking charges, and other costly surprises.

Multiple transport options mean better pricing and faster delivery. YK Freight can match your car with the most efficient route and carrier, depending on your location, timing, and budget. They help balance cost and speed, giving you choices that fit your needs without sacrificing quality or reliability.

Coordination across the supply chain ensures every step communicates seamlessly. From auction to port to final delivery, YK Freight keeps carriers, warehouses, and customers updated. This reduces errors like missed pickups, paperwork issues, or duplicate fees, saving both time and money.

For budget-conscious buyers, all of this adds up to real savings. By combining planning, flexibility, multiple options, and strong coordination, YK Freight helps cars move faster, safer, and cheaper. With their support, even small buyers or first-time shippers can take advantage of advanced supply chain strategies without the headaches of doing it all on their own.

Further Reading

Reducing Logistics Costs: Tips from YK Freight Experts

How to Cut Costs on Last Mile Delivery: Smart Tips for Savings

How to Optimize Your Oil and Gas Supply Chain for Cost and Efficiency

Building a Resilient Supply Chain: Strategies for Reliable, Cost-Friendly Delivery

ASK YOUR QUESTIONS