Understanding how oil and gas move from production to your local gas station can seem complicated. This guide explains the midstream stage — the link that keeps energy flowing smoothly. You’ll learn what midstream means, how it works, and why it’s essential for safe, cost-efficient fuel transportation. Perfect for readers who want to understand logistics and save on delivery costs.

Table of Content:

- What Are the Three Stages of the Oil and Gas Industry?

- What Is Midstream Oil and Gas?

- Why Is Midstream So Important in the Supply Chain?

- How Does the Midstream Supply Chain Work?

- What Are the Main Challenges in Midstream Logistics?

- How Does YK Freight Support Safe and Efficient Midstream Shipping?

- How Can Businesses Save Money in Midstream Operations?

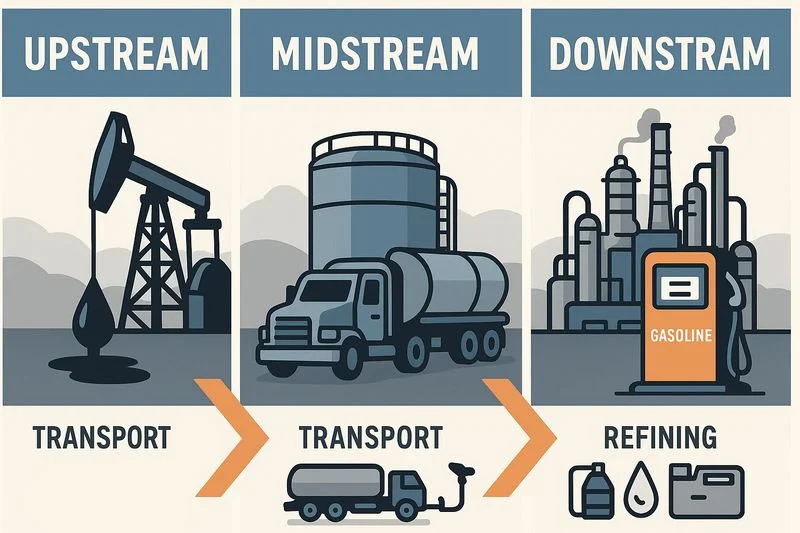

What Are the Three Stages of the Oil and Gas Industry?

The oil and gas industry operates through three main stages: upstream, midstream, and downstream. Each stage plays a unique role in bringing energy products from deep underground to your vehicle’s fuel tank or your home’s heating system.

The upstream stage focuses on finding and extracting crude oil and natural gas. This includes exploration, drilling, and production — basically everything related to getting raw materials out of the ground.

Once the oil and gas are produced, the midstream stage begins. This is where transportation and storage take place. Midstream companies handle the movement of these materials through pipelines, tankers, or trucks — ensuring they reach refineries safely and efficiently.

Finally, the downstream stage involves refining crude oil into usable products like gasoline, diesel, and jet fuel. It also covers the distribution and sale of these end products to businesses and consumers.

What Is Midstream Oil and Gas?

The midstream sector acts as the essential bridge between production and refining in the oil and gas industry. Once crude oil or natural gas is extracted from the ground (the upstream stage), it needs to be safely stored, transported, and delivered to refineries where it can be turned into usable products. That’s exactly where midstream operations come in.

The main roles of the midstream sector are transportation, storage, and distribution. This includes moving crude oil and gas through pipelines, tankers, rail, or trucks — as well as storing them in large facilities until they’re ready for refining. Without midstream, the entire energy supply chain would stall, leaving producers with no way to get their resources to market.

Midstream companies must also follow strict safety and environmental standards, since even a small mistake in transporting oil or gas can lead to spills, delays, or heavy fines. That’s why reliability is key.

Why Is Midstream So Important in the Supply Chain?

The midstream stage is where everything in the oil and gas supply chain comes together. It keeps the flow of materials steady, making sure oil and gas move smoothly from production fields to refineries — and eventually, to consumers. In simple terms, midstream operations help balance supply and demand. When there’s too much production, storage facilities hold the excess. When demand rises, those reserves are released to keep fuel supplies stable.

Reliable logistics and transportation are at the heart of this process. If midstream companies fail to move products safely or on time, the entire chain suffers — refineries can’t operate, fuel prices can rise, and customers experience shortages. That’s why every step, from pipeline transfers to truck deliveries, must follow strict safety standards and precise scheduling.

Think of it like car delivery: if your vehicle shipment is delayed or damaged, it causes stress, extra costs, and missed plans. The same happens in oil and gas — only on a much larger scale. Late deliveries or poor coordination can lead to costly downtime for refineries and millions in lost revenue.

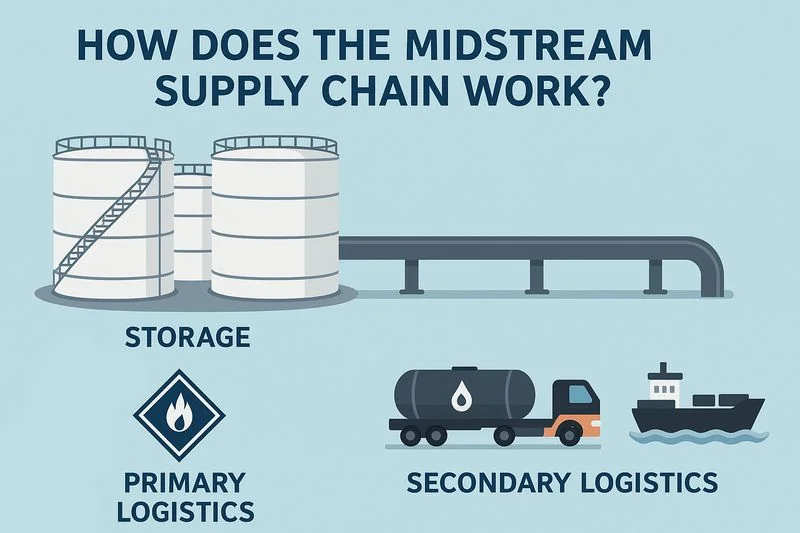

How Does the Midstream Supply Chain Work?

The midstream supply chain is the vital middle link that connects oil production with refining and distribution. It keeps energy products moving safely and efficiently through three main stages: storage, primary logistics, and secondary logistics. Each of these steps plays a unique role in keeping the oil and gas industry stable and reliable.

1. Storage

Once crude oil or natural gas is extracted, it often needs to be stored before moving to the next stage. This storage helps balance market supply and demand — ensuring there’s always enough fuel ready, even when production or consumption fluctuates. Midstream companies use large, secure tanks or tankers to hold these materials safely. Just like how car shippers store vehicles in secure lots before transport, storage facilities protect valuable fuel from leaks, damage, or contamination.

2. Primary logistics

After storage, the next stage is moving oil and gas across the country — mainly through pipelines. These pipelines are built to handle high pressure and long distances while meeting strict safety and environmental standards. It’s one of the most efficient and cost-effective ways to transport large volumes of fuel. If pipelines are the “highways” for oil and gas, companies like YK Freight are the skilled operators ensuring everything moves on schedule without delays or safety issues.

3. Secondary logistics

Once the materials reach regional hubs or terminals, they need to be delivered to final destinations such as refineries, warehouses, or industrial plants. This stage relies on different transport modes — trucks, rail, and barges — to complete the journey. Each method requires careful coordination to avoid spills, delays, or extra costs.

What Are the Main Challenges in Midstream Logistics?

Running midstream operations might sound straightforward — just store and move oil or gas — but in reality, it’s one of the most complex and tightly regulated parts of the energy supply chain. Every step involves strict safety rules, expensive equipment, and constant monitoring. Even a small mistake can lead to huge financial losses or environmental damage.

One of the biggest challenges is pipeline maintenance. Pipelines stretch for thousands of miles across the country, often through rough terrain or populated areas. Over time, they can develop leaks or corrosion. A single unnoticed crack could result in a costly spill or even an environmental disaster. Regular inspections, repairs, and safety checks are crucial — but they also take time and money.

Another major challenge is environmental regulation. Governments require midstream companies to follow strict standards to prevent pollution and protect natural habitats. That means detailed documentation, frequent audits, and expensive compliance procedures. While this adds to operational costs, it’s essential for keeping both the environment and workers safe.

Then there’s transportation safety. Whether moving fuel through pipelines, trucks, or rail, each method carries risk. Accidents, bad weather, or equipment failure can delay deliveries and create financial headaches for everyone involved. For example, a truck carrying fuel that breaks down on the road can disrupt supply schedules and raise costs for downstream companies — just like a delayed car shipment can frustrate customers waiting for delivery.

How Does YK Freight Support Safe and Efficient Midstream Shipping?

In the midstream oil and gas industry, safe and efficient transportation isn’t optional — it’s essential. Every gallon of oil or unit of natural gas that moves through the supply chain must be handled with precision, care, and full regulatory compliance. That’s where YK Freight comes in.

With years of logistics experience, YK Freight specializes in managing sensitive and high-value cargo like fuel, chemicals, and other energy materials. The company follows all required federal and environmental transport standards, ensuring every shipment meets safety expectations and legal requirements. From pipeline transfers to ground deliveries, every step is monitored to prevent leaks, damage, or costly delays.

What makes YK Freight stand out is its focus on efficiency through smart route planning. By analyzing the best paths, scheduling shipments strategically, and avoiding unnecessary detours, the company helps clients save both time and money. For businesses that operate on tight budgets, this optimization can make a huge difference — reducing fuel costs, labor time, and potential penalties for late or unsafe deliveries.

YK Freight’s professional carriers also undergo specialized training to handle hazardous and sensitive materials safely. This minimizes the risks of accidents or non-compliance — something that often happens when companies try to handle transportation on their own. Instead of facing expensive fines or damaged goods, YK Freight’s clients benefit from secure, reliable, and fully compliant service.

How Can Businesses Save Money in Midstream Operations?

The midstream oil and gas sector is all about balance — moving materials safely while keeping costs under control. For many companies, especially those operating on tight budgets, finding ways to cut delivery expenses without sacrificing safety or reliability is a top priority. Luckily, there are several smart strategies that can make a real difference.

One of the most effective ways to save is through shipment consolidation. Instead of sending multiple small loads separately, combining them into a single, well-organized shipment can reduce fuel costs, driver hours, and handling fees. It’s similar to how car shippers group multiple vehicles in one carrier to lower delivery costs — fewer trips mean more savings.

Another major money-saver is strategic route planning. Optimizing routes helps minimize mileage, avoid traffic delays, and cut down on fuel use. YK Freight uses advanced logistics tools to design efficient delivery routes that keep shipments on schedule and budgets under control. The result is faster, smoother transportation with fewer unexpected expenses.

Businesses should also focus on avoiding downtime. When pipelines, storage tanks, or trucks sit idle, it costs money — in labor, equipment maintenance, and lost productivity. Keeping operations running smoothly through proper scheduling and maintenance can have a big impact on long-term savings.

Finally, the most valuable cost-saving step is to work with experienced carriers like YK Freight. Professional logistics companies understand safety regulations, know how to handle sensitive cargo, and can prevent costly mistakes that come from DIY or inexperienced shipping.

Further Reading

How to Optimize Your Oil and Gas Supply Chain for Cost and Efficiency

How Oil and Gas Companies Can Save on Logistics and Cut Transportation Costs

4 Best Transportation Methods for Oil and Gas Shipping Explained

Oil and Gas Safety: Top 3 Practices for Risk-Free Transportation

ASK YOUR QUESTIONS