The chemical supply chain is complex, fast-changing, and full of challenges—from strict regulations to market fluctuations. For businesses and budget-conscious shippers, understanding these hurdles can help plan better, avoid delays, and save money. This guide breaks down the key challenges of the chemical supply chain in simple terms, showing practical ways to navigate them and keep operations running smoothly.

Table of Content:

- What Is a Chemical Supply Chain?

- Why Is Demand Uncertainty a Big Challenge?

- How Do Emerging Technologies Impact the Chemical Supply Chain?

- How Does Industry Consolidation and Growing Competition Create Pressure?

- Why Are Regulatory Requirements So Complex?

- How Do Supply Chain Disruptions Affect Operations?

- How Can Companies Balance Cost and Safety?

- How Can Flexibility Improve the Chemical Supply Chain?

What Is a Chemical Supply Chain?

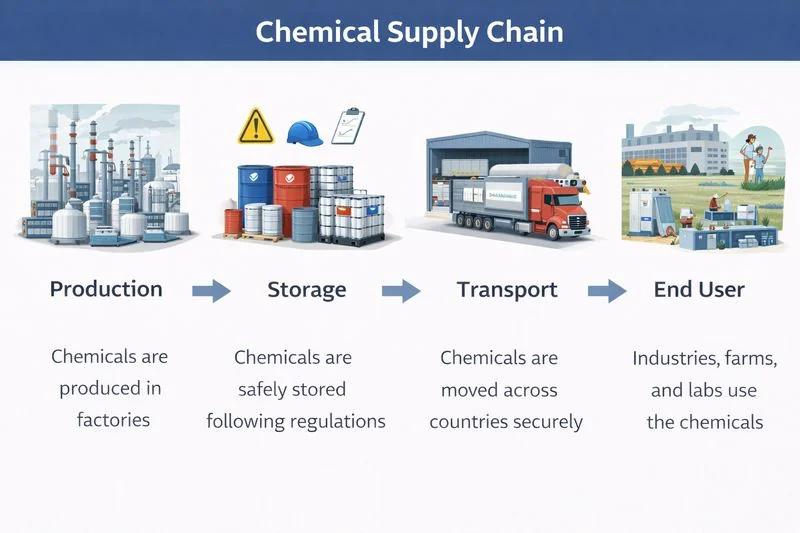

A chemical supply chain is the journey that chemicals take from production to the people or industries that need them. It’s not just about making a product in a factory—it’s about storing it safely, moving it across countries, following strict rules, and making sure it arrives on time and in good condition. Think of it as a carefully planned highway system for chemicals, where every step matters.

The chemical industry is massive. It generates more than $5 trillion in sales every year and touches almost every part of our lives. Chemicals are used to grow food, build houses, power factories, and even make the medicine we rely on. Without a smooth chemical supply chain, everyday industries like nutrition, agriculture, construction, and healthcare would face delays and higher costs.

To make it relatable, imagine shipping a car across the country. You need the right carrier, proper loading, the correct route, and careful handling to avoid damage. Chemicals require the same careful planning—sometimes even more because they can be hazardous, sensitive to temperature, or require special containers. Just like you wouldn’t want your budget car to get scratched or delayed, industries can’t afford mistakes in the chemical supply chain. Every link has to work perfectly to keep products safe, on time, and affordable.

Why Is Demand Uncertainty a Big Challenge?

One of the biggest headaches in the chemical supply chain is demand uncertainty. This means that companies never know exactly how much of a chemical their customers will need or when they will need it. Customer orders can change quickly, markets can shift, and unexpected events—like natural disasters or sudden spikes in demand—can throw even the best plans off track.

On top of that, commoditization makes things even trickier. In simple terms, commoditization means customers have multiple suppliers to choose from for the same product. If one supplier is late or expensive, the customer can quickly switch to another. This creates constant pressure to meet deadlines and maintain competitive pricing.

For budget-conscious readers, here’s a way to imagine it: think about trying to get a used car shipped quickly and safely. You schedule the transport, but the seller changes the pickup date, the transport company has a delay, or the route has unexpected issues. Now you have to adjust your plan, stay in contact with everyone, and make sure the car arrives without damage—all while keeping costs low. Chemical companies face the same challenge but on a much bigger scale, with thousands of products, strict safety rules, and tight timelines.

How Do Emerging Technologies Impact the Chemical Supply Chain?

When most people hear “new technology” or “digitalization,” they think of easy improvements—faster computers, smarter apps, or better tracking systems. In the chemical industry, however, emerging technologies can actually be a big challenge. Chemicals are often produced in large quantities, stored in specialized containers, and transported under strict safety rules. Introducing new software, automation tools, or digital tracking systems into this rigid setup isn’t as simple as flipping a switch.

Adopting these tools takes time, training, and careful planning. Employees need to learn new systems, existing processes may need adjustments, and mistakes during the transition can disrupt operations. Even though the technology ultimately improves efficiency and service, the initial effort can slow things down—and that’s a real risk for companies that rely on precise timing and handling.

To make it relatable: imagine upgrading the software or tracking system for a car shipment. It sounds helpful—better tracking, fewer mistakes—but first you have to teach your team how to use it, fix any glitches, and make sure all routes and schedules are properly updated. During this period, delays or errors can happen, and customers may feel the impact. The same happens in the chemical supply chain.

How Does Industry Consolidation and Growing Competition Create Pressure?

The chemical industry is highly competitive, and this competition creates real pressure for companies. One major trend is industry consolidation, where smaller chemical companies merge with larger ones or are bought out to survive. This often happens because the market has overcapacity—too many suppliers producing similar products—and growth in traditional markets like Europe and the U.S. is slowing. Companies are now looking toward Asia and the Middle East, where demand is rising, but entering these markets can be expensive and complicated.

Smaller players often struggle to keep up. They may lack the resources to compete on price, invest in technology, or expand internationally. If they fail, they risk going out of business entirely. For budget-conscious shippers, this is important to understand: when a chemical supplier is unstable or under pressure, service reliability can suffer. Delays, mistakes, or sudden service interruptions become more likely.

This is where choosing a reliable and consolidated partner like YK Freight makes a difference. Just as a larger, well-established transport company can safely and predictably ship your car, a stable logistics partner ensures that chemical shipments—or any cargo—arrive on time and intact, without the risk of “bankruptcy surprises” or sudden service failures. Stability and experience help keep costs predictable, even when the market is chaotic.

Why Are Regulatory Requirements So Complex?

One of the toughest challenges in the chemical supply chain is regulatory requirements. Chemicals can be hazardous, flammable, or sensitive to temperature, which means companies must follow strict safety, handling, and environmental rules at every step—from production to storage to transportation. Even a small mistake can create serious risks for workers, communities, or the environment.

Failing to follow these rules can lead to delays, heavy fines, or even legal trouble. For example, a shipment might be held at customs because paperwork is missing, or a transport company may need to return a load if the containers don’t meet safety standards. These complications can slow down the entire supply chain and increase costs—problems that budget-conscious companies and customers want to avoid.

To make it relatable, think about vehicle transport. When shipping a car, you have to complete paperwork, declare fluids, and follow safety rules. Missing a step—like forgetting to drain fuel or provide the right documents—can delay the delivery or even prevent the shipment entirely. The same principle applies to chemicals: attention to detail and compliance is essential to keep everything moving smoothly and safely.

How Do Supply Chain Disruptions Affect Operations?

Supply chains are delicate systems, and even small disruptions can have a big impact. In the chemical industry, weather events, accidents, or shortages of raw materials can slow down or stop the movement of products. For example, a storm can delay trucks or ships, a spill at a storage facility can halt operations, or a shortage of a key ingredient can stop production altogether.

The pandemic showed just how fragile supply chains can be. Sudden spikes in demand for certain chemicals, like those used in cleaning products or pharmaceuticals, created shortages and delays around the world. Even companies with solid planning struggled to keep up, which caused frustration and increased costs.

Budget-conscious readers can relate this to vehicle shipping delays. Imagine scheduling a car delivery for a tight budget, only to face last-minute route changes, traffic accidents, or carrier delays. Suddenly, your car arrives late, and extra fees start piling up. Just like with chemical shipments, disruptions require flexibility, communication, and contingency planning to avoid bigger problems.

How Can Companies Balance Cost and Safety?

Transporting and storing chemicals safely is expensive. Special containers, temperature controls, protective equipment, and trained staff all add up. Cutting corners on these measures may lower costs in the short term, but it increases the risk of accidents, product damage, or regulatory fines. On the other hand, prioritizing safety without considering costs can make operations prohibitively expensive.

This creates a constant trade-off between affordability and reliability. Companies must carefully plan how to protect their products while keeping shipping costs manageable. Choosing the wrong approach can lead to delays, damaged goods, or unexpected expenses—problems that budget-conscious customers want to avoid.

How Can Flexibility Improve the Chemical Supply Chain?

Flexibility is a key factor in keeping the chemical supply chain running smoothly. Markets change, customer demands shift, and new technologies are constantly introduced. Companies that can adapt quickly to these changes are better positioned to avoid delays, reduce costs, and maintain reliable service.

Sometimes, even small operational changes can make a big difference. For example, adjusting production schedules to match sudden demand spikes, rerouting shipments around a blocked port, or temporarily using alternative storage facilities can prevent delays and minimize losses. These are small tweaks that help the entire supply chain stay efficient and responsive.

For budget-conscious readers, think of this like car transport. Being flexible with delivery routes, timing, or pickup locations can save both money and stress. If a transporter can adjust to traffic, road closures, or last-minute schedule changes, your car arrives on time without extra costs or headaches. In the same way, chemical companies that embrace flexibility can keep shipments on track, maintain safety, and avoid unnecessary expenses—even in unpredictable situations.

Further Reading

How to Optimize Your Oil and Gas Supply Chain for Cost and Efficiency

Building a Resilient Supply Chain: Strategies for Reliable, Cost-Friendly Delivery

What Are Hazardous Materials and How to Ship Them Safel

ASK YOUR QUESTIONS