Supply chain management keeps products moving smoothly from suppliers to customers. This guide explains how it works, why it matters for costs and efficiency, and how small businesses can save on shipping while delivering on time.

Table of Content:

- What is supply chain management and why does it matter?

- What processes are included in a supply chain?

- How does transportation affect supply chain efficiency?

- Why is communication and visibility crucial in a supply chain?

- How does finance play a role in supply chain management?

- What technologies can improve supply chain efficiency?

- How can small businesses save on logistics costs with YK Freight?

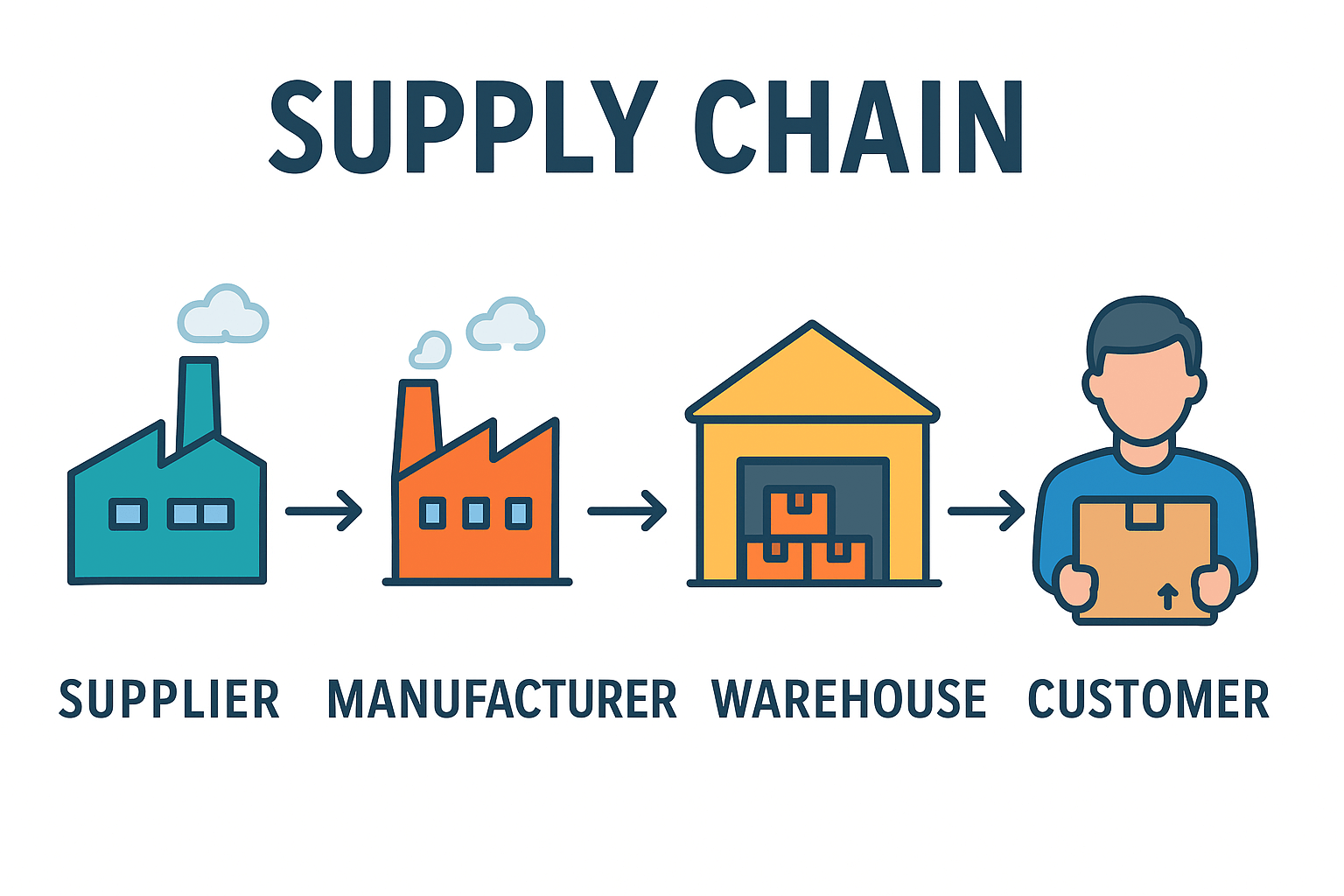

What is supply chain management and why does it matter?

Supply chain management (SCM) is the process of overseeing how goods move from the supplier to the manufacturer, and eventually to the customer. It covers everything from sourcing raw materials, production, and transportation, to delivery and sales. In simple terms, it’s the journey of a product from start to finish, carefully planned to save time, reduce costs, and keep customers happy.

For small businesses, especially those dealing with auto parts or vehicle shipping, effective supply chain management can make a huge difference. Imagine you run a small car accessories business. If your supplier delivers parts late or your shipping is disorganized, your customers may have to wait longer, which can hurt your reputation and sales. On the other hand, a well-managed supply chain ensures items arrive on time, inventory is tracked correctly, and your business runs efficiently.

Proper supply chain management also helps reduce transportation costs. By planning routes, consolidating shipments, and choosing the right carriers, businesses can save money without compromising delivery speed. At the same time, it boosts productivity: employees spend less time fixing shipping mistakes and more time focusing on growing the business.

What processes are included in a supply chain?

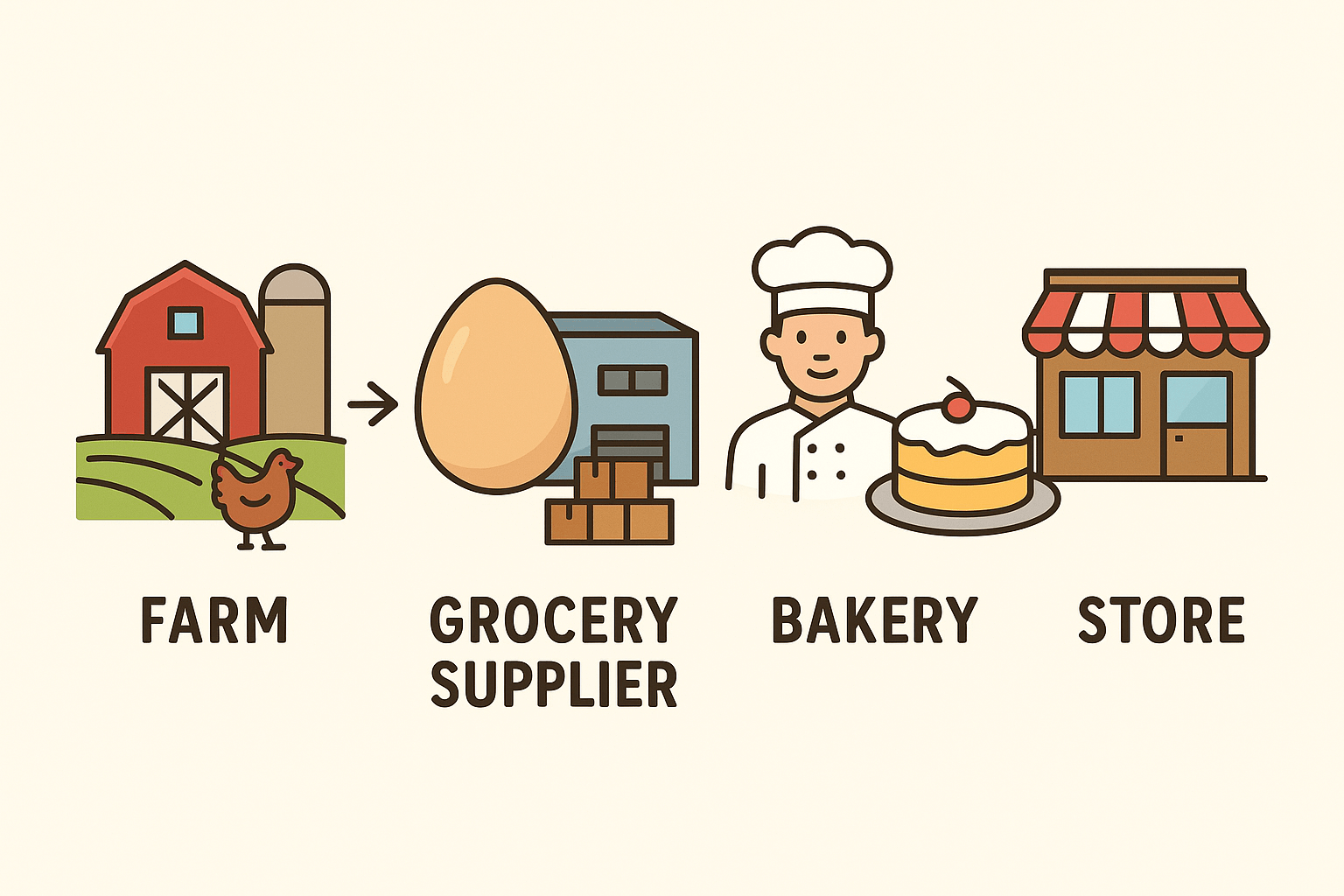

A supply chain involves several interconnected steps that move a product from its raw form to the hands of the customer. To make it easy to understand, let’s use a simple example: the journey of an egg from a farm to a finished cake in a store.

First, the eggs are collected at the farm and transported to a grocery supplier. This step involves sourcing and initial transportation—two key processes in any supply chain. Next, a bakery buys the eggs along with other ingredients and uses them to bake a cake. This is the production stage, where raw materials are transformed into finished goods.

After the cake is ready, it either stays in the bakery for local sales or is transported to a grocery store to reach customers. This final step covers distribution and delivery. Each movement of the product—whether it’s shipping ingredients or delivering the finished cake—requires planning, tracking, and coordination.

Even though this example is simple, real-world supply chains can be much more complex. Products may pass through multiple suppliers, warehouses, and transportation methods before reaching the final customer. Understanding each step is crucial because inefficiencies at any point—like delayed delivery or damaged goods—can increase costs and affect customer satisfaction.

How does transportation affect supply chain efficiency?

Transportation is one of the most important elements of any supply chain. It moves goods between suppliers, manufacturers, warehouses, and customers, making sure products arrive where they’re needed, when they’re needed. For small businesses, especially those shipping vehicles or auto parts, efficient transportation can save money, reduce delays, and make logistics much easier to manage.

Think about a small car parts business. If a supplier’s delivery is slow or unreliable, your orders may be delayed, leaving customers frustrated and hurting your reputation. On the other hand, using well-planned transportation routes ensures products move smoothly from suppliers to warehouses, and eventually to customers, without unnecessary stops or delays.

Organized transportation also helps reduce costs. Consolidating shipments, choosing the right carriers, and planning routes efficiently can lower fuel expenses, reduce extra handling fees, and prevent rushed deliveries that often come at a premium. For example, shipping multiple auto parts together in one truck rather than sending them separately can save both time and money.

Additionally, predictable transportation allows small businesses to plan inventory and sales more effectively. Knowing when shipments will arrive means you can avoid stock shortages, keep your production running, and meet customer expectations consistently.

Why is communication and visibility crucial in a supply chain?

A supply chain involves many moving parts: manufacturers, suppliers, distributors, and retailers all need to work together. Without clear communication, even small businesses can face delays, errors, or extra costs. For budget-conscious businesses, keeping everyone informed is essential to avoid surprises that could affect both the bottom line and customer satisfaction.

Take a small auto parts business as an example. If the manufacturer doesn’t inform the distributor about a shipment delay, the retailer might run out of stock, leaving customers waiting and potentially turning to competitors. Regular communication between all parties ensures that everyone knows what’s happening at each stage, making it easier to plan and react quickly if problems arise.

Visibility is equally important. This means having a clear view of the entire supply chain—from raw materials to finished products—so you can track shipments, monitor inventory, and make strategic decisions. With good visibility, small businesses can identify bottlenecks, optimize routes, and even adjust orders before delays or shortages occur.

For example, a small car delivery service working with YK Freight can track every shipment in real time. Knowing exactly where a vehicle or part is allows the business to inform customers, avoid unnecessary storage costs, and keep the delivery process efficient.

How does finance play a role in supply chain management?

Finance is a critical part of supply chain management. Every step in the chain—sourcing materials, manufacturing, transporting goods, and delivering products—comes with costs that need to be tracked and managed. For small businesses, keeping control over these expenses is essential to avoid unexpected bills and maintain a healthy budget.

Proper financial management starts with accurate documentation. Recording invoices, payments, and receipts ensures you know exactly how much each shipment or production batch costs. For example, a small auto parts business that tracks shipping fees, storage costs, and supplier payments can easily identify where money is being spent and where savings are possible.

Budgeting is also crucial. By understanding the financial flow of the supply chain, small businesses can plan ahead, negotiate better rates with carriers like YK Freight, and avoid last-minute rush charges that can eat into profits. It also helps in decision-making: knowing the costs of different transportation options or suppliers allows the business to choose the most cost-effective solution.

Finally, financial oversight helps prevent errors or fraud. Proper records make it easier to spot overcharges, duplicate payments, or discrepancies in shipments, which could otherwise create hidden costs.

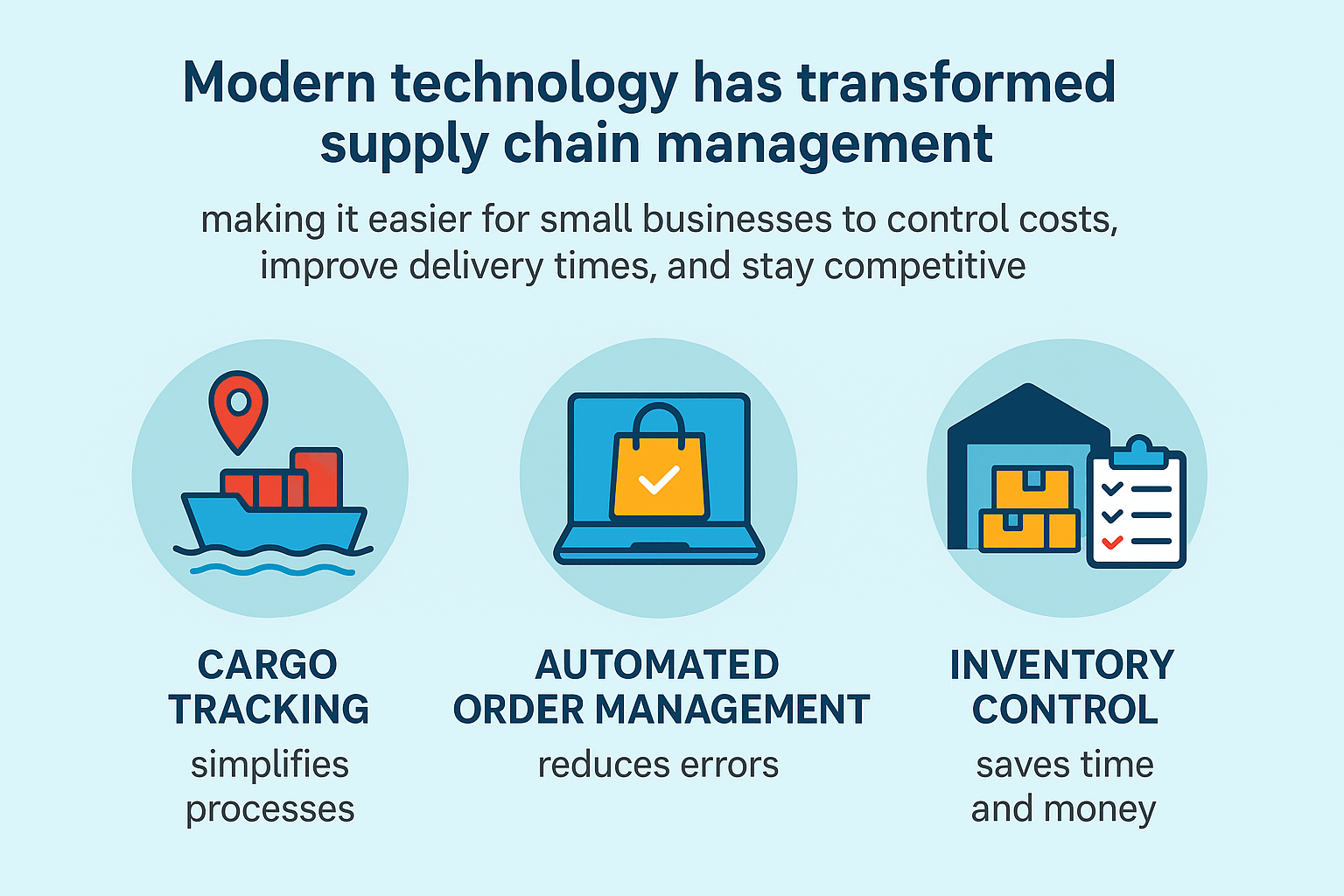

What technologies can improve supply chain efficiency?

Modern technology has transformed supply chain management, making it easier for small businesses to control costs, improve delivery times, and stay competitive. Even on a tight budget, using the right tools can simplify processes, reduce errors, and save both time and money.

One key technology is cargo tracking systems. With real-time tracking, small businesses can monitor shipments at every stage, from the supplier to the customer. For example, an auto parts business working with YK Freight can see exactly where a delivery truck is, estimate arrival times, and update customers instantly. This reduces uncertainty, prevents lost shipments, and improves customer satisfaction.

Automated order management is another useful tool. It helps businesses process orders faster and more accurately by automatically updating inventory, generating invoices, and notifying carriers. This reduces human errors, speeds up operations, and allows employees to focus on more strategic tasks, like growing the business or improving customer service.

Inventory control software also plays a critical role. It helps track stock levels, manage warehouse storage, and forecast demand. For small businesses, this means avoiding overstocking or running out of products, which can lead to wasted money or lost sales. For instance, a small car delivery company can plan shipments better and consolidate orders to reduce transport costs.

How can small businesses save on logistics costs with YK Freight?

Partnering with YK Freight can make a big difference for small businesses looking to control shipping costs without sacrificing service quality. For companies with limited budgets—like those shipping vehicles or auto parts—YK Freight provides solutions that optimize transportation, streamline operations, and keep customers satisfied.

One way YK Freight helps is through cost-effective transportation options. By consolidating shipments, planning efficient routes, and offering flexible delivery schedules, businesses can reduce fuel and handling costs. For example, a small auto parts company can ship multiple orders together instead of separately, lowering overall expenses while ensuring products reach customers on time.

Another benefit is reliable supply chain management support. With YK Freight, small businesses gain visibility into their shipments, access to real-time tracking, and clear communication at every step. This helps prevent delays, reduces errors, and allows owners to focus on running their business instead of constantly managing logistics problems.

YK Freight also provides guidance on strategic decisions. For example, they can advise on the most cost-efficient shipping methods for different types of cargo or suggest ways to combine orders and reduce unnecessary trips. This hands-on support ensures businesses make smarter decisions that save money over time.

Finally, working with YK Freight helps maintain high-quality customer service. Timely deliveries, accurate tracking, and professional handling of shipments build trust with customers, encouraging repeat business and positive reviews—critical for small businesses operating on tight margins.

Further Reading:

What is Freight and Logistics?

What is 3PL Experience? Benefits of Third-Party Logistics

What is Managed Transportation?

Optimizing Supply Chains with Container Drayag

ASK YOUR QUESTIONS