Managing logistics in the oil and gas industry can be costly and complex. For budget-conscious companies, every dollar counts. This guide explains practical strategies to reduce transportation expenses, optimize supply chains, and improve efficiency, helping businesses save money without compromising safety or reliability.

Table of Content:

- Why Is Logistics Management a Challenge for Oil and Gas Companies?

- How Can Companies Analyze Their Internal Processes to Reduce Costs?

- How Can a Transportation Management System (TMS) Help Cut Logistics Expenses?

- How Can Analytics and Strategic Planning Optimize Supply Chain Operations?

- What Practical Steps Can Oil and Gas Companies Take to Save on Logistics?

Why Is Logistics Management a Challenge for Oil and Gas Companies?

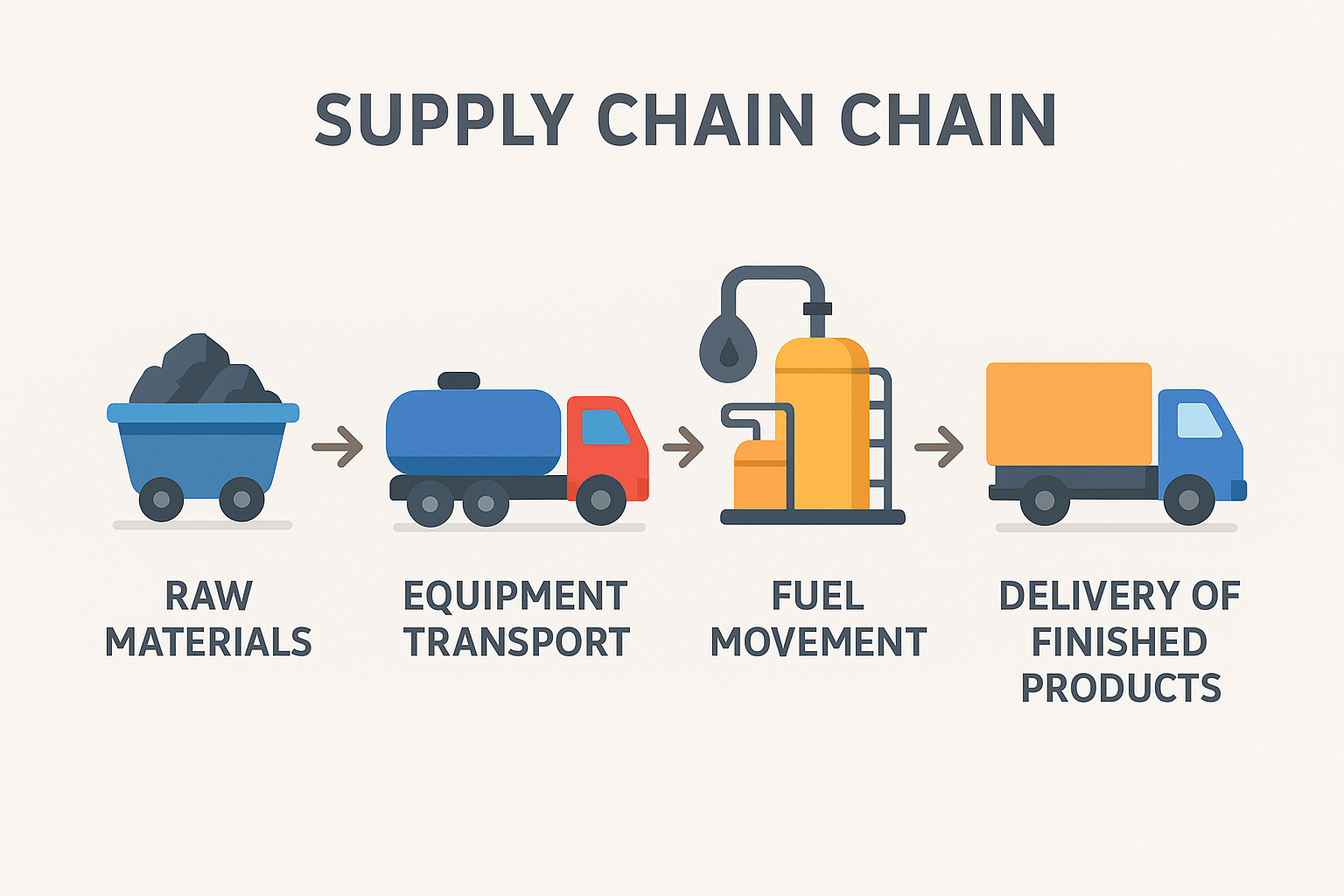

Managing logistics in the oil and gas industry is not easy. Supply chains are complex, involving multiple steps such as sourcing raw materials, transporting equipment, moving fuel, and delivering finished products. Each stage requires careful coordination, specialized vehicles, and strict safety measures. Unlike simpler shipments, delays or mistakes in oil and gas logistics can be costly, risky, and time-consuming.

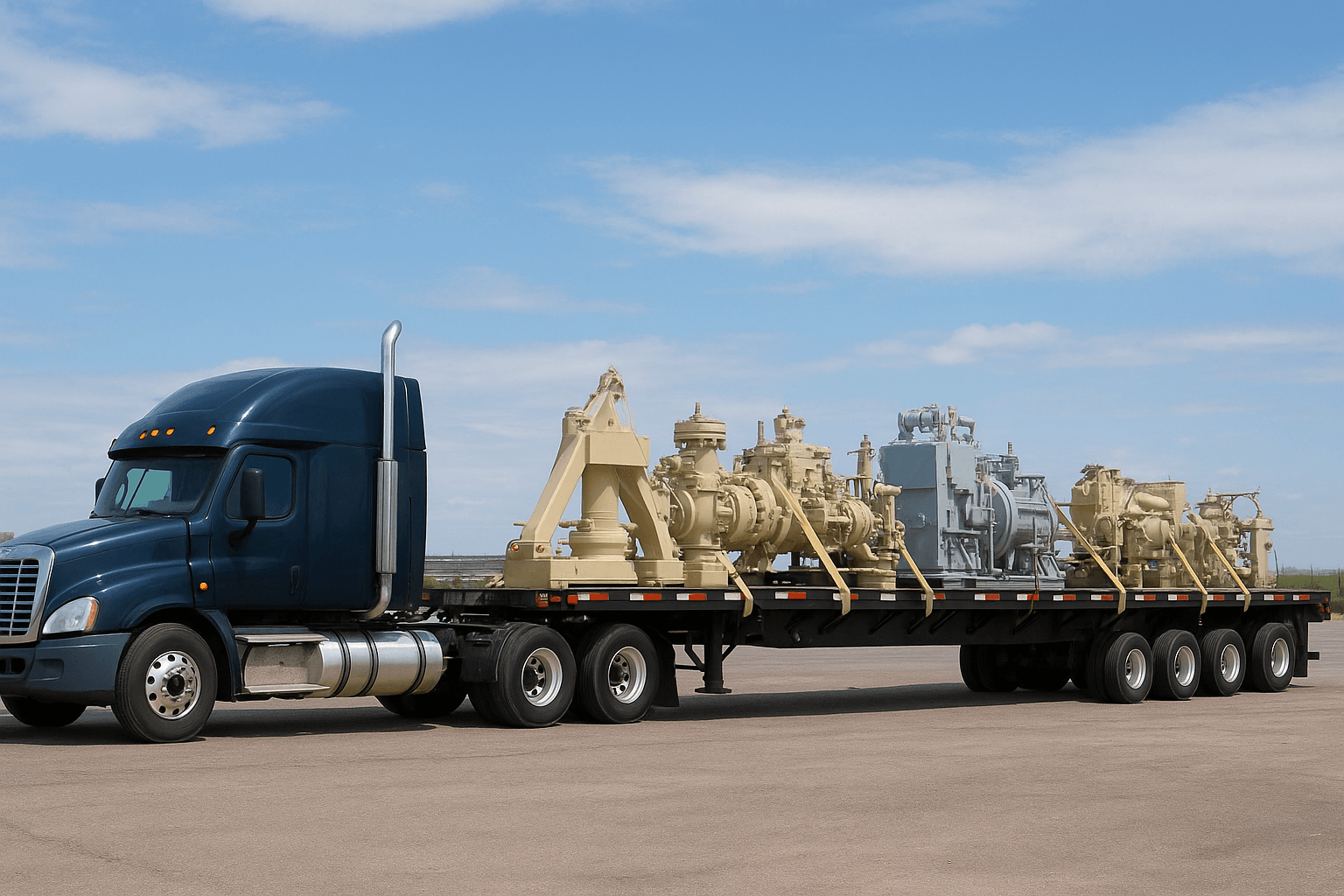

Transportation costs are a major challenge. Moving heavy equipment, chemicals, or fuel over long distances requires specialized carriers, permits, and insurance. Fuel prices, labor, and maintenance add even more to the total expense. Operational inefficiencies, such as empty return trips, poor route planning, or underutilized trucks, can drive costs higher and eat into tight budgets.

Budget-conscious companies often struggle to maintain cost-effective operations. Small and medium-sized operators may not have the resources to hire logistics experts, invest in advanced tracking tools, or negotiate favorable rates with carriers. Without careful management, even minor inefficiencies can quickly add up, leading to higher expenses and wasted time.

How Can Companies Analyze Their Internal Processes to Reduce Costs?

Before implementing any new strategies, oil and gas companies need to take a close look at their current logistics operations. Reviewing existing processes helps identify where time, money, or resources are being wasted. Without this step, new solutions may not address the real problems, and efforts to cut costs could fail.

One effective approach is to hire external analysts who specialize in logistics. These experts bring an objective perspective and experience with similar supply chains, making it easier to pinpoint inefficiencies that internal teams might overlook. For smaller companies, internal staff can also perform process audits if outside help is not an option, using checklists, data analysis, and feedback from drivers and warehouse personnel.

Key areas to examine include shipment scheduling, vehicle utilization, warehouse operations, route planning, and handling procedures. For example, a company might discover that trucks are returning empty on certain routes or that some shipments are repeatedly delayed due to poor coordination. Identifying these weak points is crucial because it allows management to focus on the areas that will deliver the most significant cost savings.

How Can a Transportation Management System (TMS) Help Cut Logistics Expenses?

A Transportation Management System (TMS) is a powerful tool that helps oil and gas companies manage shipments more efficiently and reduce logistics costs. By centralizing all transportation data in one place, a TMS provides full visibility into the supply chain. Companies can track every shipment, monitor vehicle routes, and ensure that goods are delivered on time and in good condition. This transparency makes it easier to spot inefficiencies and make smarter decisions.

A TMS also tracks key metrics, such as fuel usage, delivery times, carrier performance, and shipment costs. It can highlight inconsistencies between rates and final bills, helping companies identify overcharges or billing errors. Additionally, the system captures negative spending trends, showing where money is being wasted, which allows management to take corrective action before costs spiral out of control.

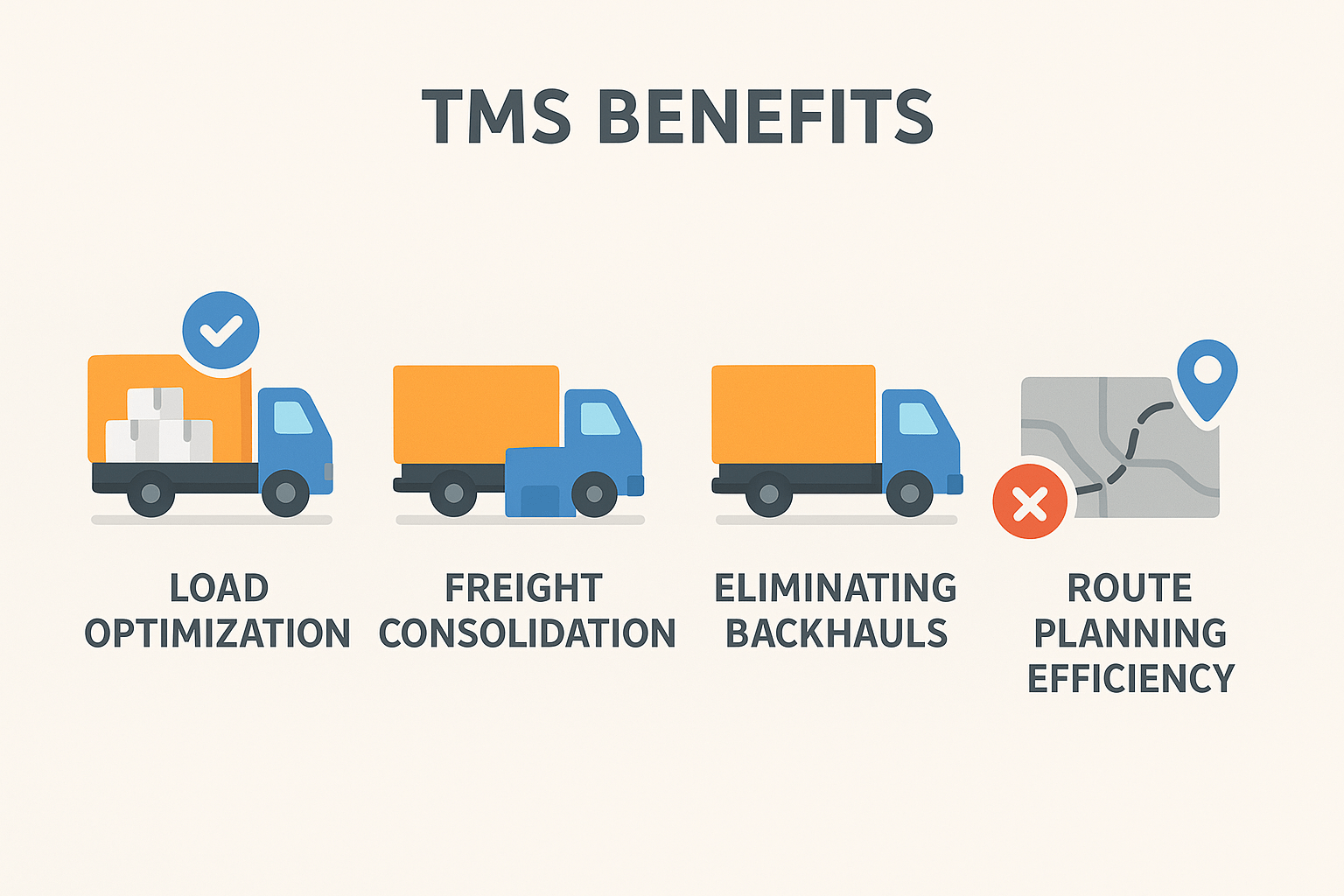

Beyond tracking and analysis, a TMS offers several practical cost-saving features. Load optimization ensures trucks are filled efficiently, avoiding wasted space and extra trips. Freight consolidation combines multiple shipments into one, reducing the number of vehicles on the road and lowering fuel costs. Eliminating backhauls—trucks returning empty—further saves money, while reducing extra miles through smarter route planning cuts both fuel and labor expenses.

How Can Analytics and Strategic Planning Optimize Supply Chain Operations?

Data-driven decision-making is key to optimizing supply chains in the oil and gas industry. By analyzing accurate data from past shipments, fuel usage, delivery times, and carrier performance, companies can forecast future needs and plan their operations more efficiently. This allows managers to anticipate bottlenecks, schedule resources better, and avoid costly delays.

Analytics also helps identify unnecessary processes that add little value but increase costs. For example, a company may discover redundant steps in handling equipment, overstaffed shifts, or inefficient routing. Eliminating these inefficiencies streamlines operations, reduces labor and fuel costs, and makes the entire supply chain more reliable.

Strategic planning based on accurate insights turns this analysis into actionable savings. Companies can optimize routes, consolidate shipments, choose the most cost-effective carriers, and schedule deliveries to avoid peak traffic or high fuel rates. Over time, these improvements lead to real, measurable reductions in logistics costs, while maintaining safety and service quality.

What Practical Steps Can Oil and Gas Companies Take to Save on Logistics?

For oil and gas companies looking to cut costs, practical planning and smart use of resources are essential. One effective strategy is consolidating shipments. By combining multiple deliveries into a single load, companies reduce the number of trips, lower fuel costs, and maximize truck space. For example, a small supplier shipping equipment to multiple drilling sites can coordinate deliveries through YK Freight to save on transportation expenses.

Careful route planning is another key step. Choosing the most efficient routes, avoiding congested areas, and scheduling shipments at optimal times can significantly reduce fuel and labor costs. Even minor changes in scheduling or routing can prevent wasted miles and help meet tight budgets without delaying deliveries.

Negotiating with carriers or using a trusted logistics partner like YK Freight can also yield major savings. Experienced providers can access discounted rates, provide a wide range of carrier options, and manage complex shipments, from heavy machinery to fuel, ensuring safe and timely deliveries.

Finally, leveraging technology and expertise helps maintain safety and reliability while reducing costs. Tools for shipment tracking, performance monitoring, and real-time communication prevent errors, minimize delays, and ensure compliance with regulations.

By consolidating loads, planning efficient routes, negotiating rates, and partnering with YK Freight, budget-conscious oil and gas companies can save money on logistics without compromising safety or operational reliability. Smart planning and professional support make cost-effective shipping possible, even for complex and heavy shipments.

Further Reading

How to Optimize Your Oil and Gas Supply Chain for Cost and Efficiency

Reducing Logistics Costs: Tips from YK Freight Experts

What Is Cargo Consolidation and How It Saves You Money on Shipping

Discover the Top Benefits of Intermodal Transport for Safe and Cost-Effective Shippin

ASK YOUR QUESTIONS