Highway congestion costs time, money, and stress for everyone involved in freight transportation. For budget-conscious shippers, delays mean higher fuel costs and late deliveries. This guide explains how traffic jams affect shipping, why deadlines are hard to predict, and practical strategies—like smart route planning and multi-modal logistics—to save money and ensure your vehicle arrives on time with YK Freight.

Table of Content:

- How Much Does Highway Congestion Cost the Trucking Industry?

- What Are the Negative Impacts of Road Congestion?

- Why Is It Hard to Forecast Shipping Deadlines During Congestion?

- How Can Route Planning Reduce the Impact of Congestion?

- Can Near-Shoring and Centralized Warehousing Help?

- How Can Infrastructure and Multi-Modal Transportation Make a Difference?

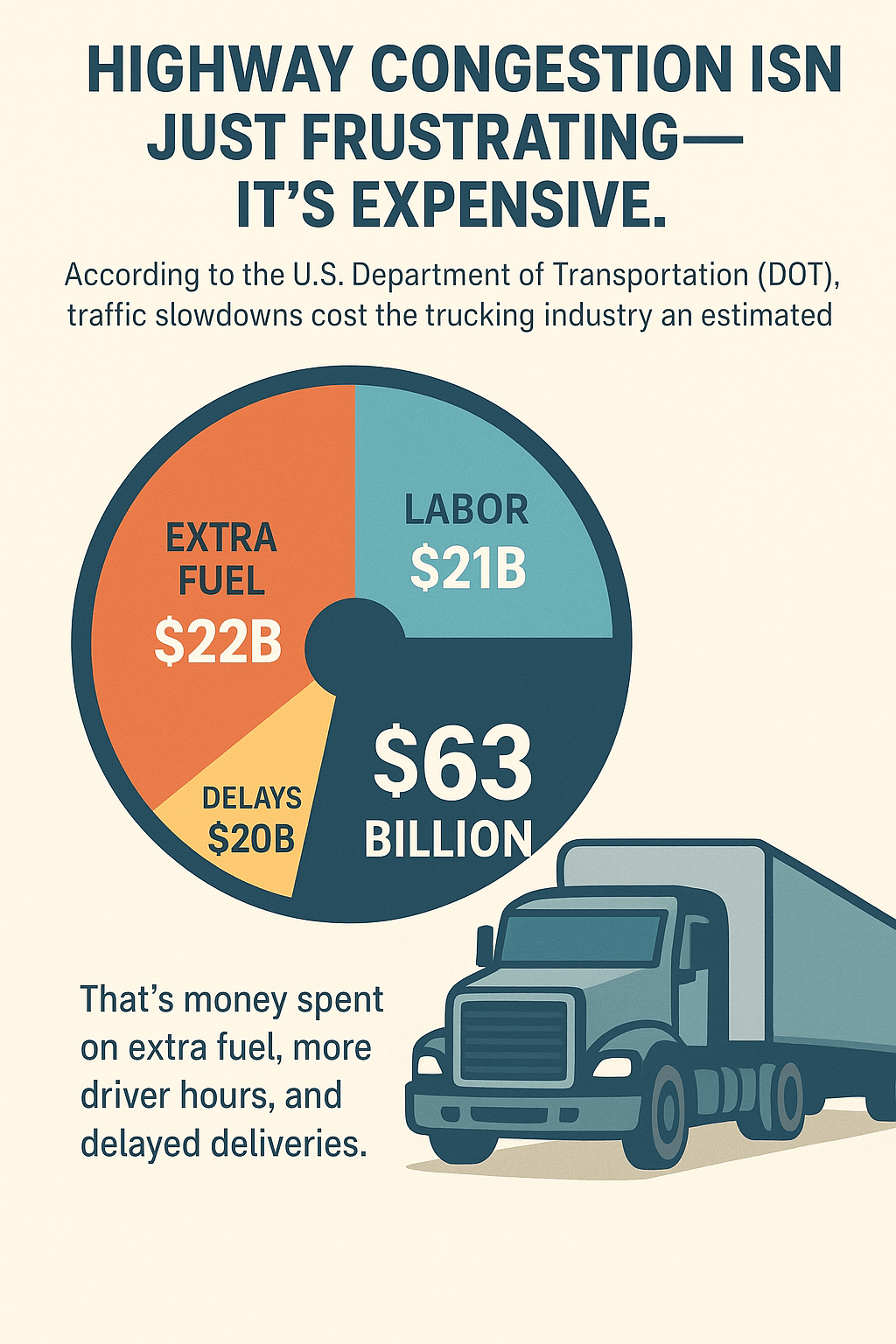

How Much Does Highway Congestion Cost the Trucking Industry?

Highway congestion isn’t just frustrating—it’s expensive. According to the U.S. Department of Transportation (DOT), traffic slowdowns cost the trucking industry an estimated $63 billion every year. That’s money spent on extra fuel, more driver hours, and delayed deliveries. In fact, 13,500 miles of U.S. highways are regularly moving slower than their posted speed limits, creating constant bottlenecks for truckers.

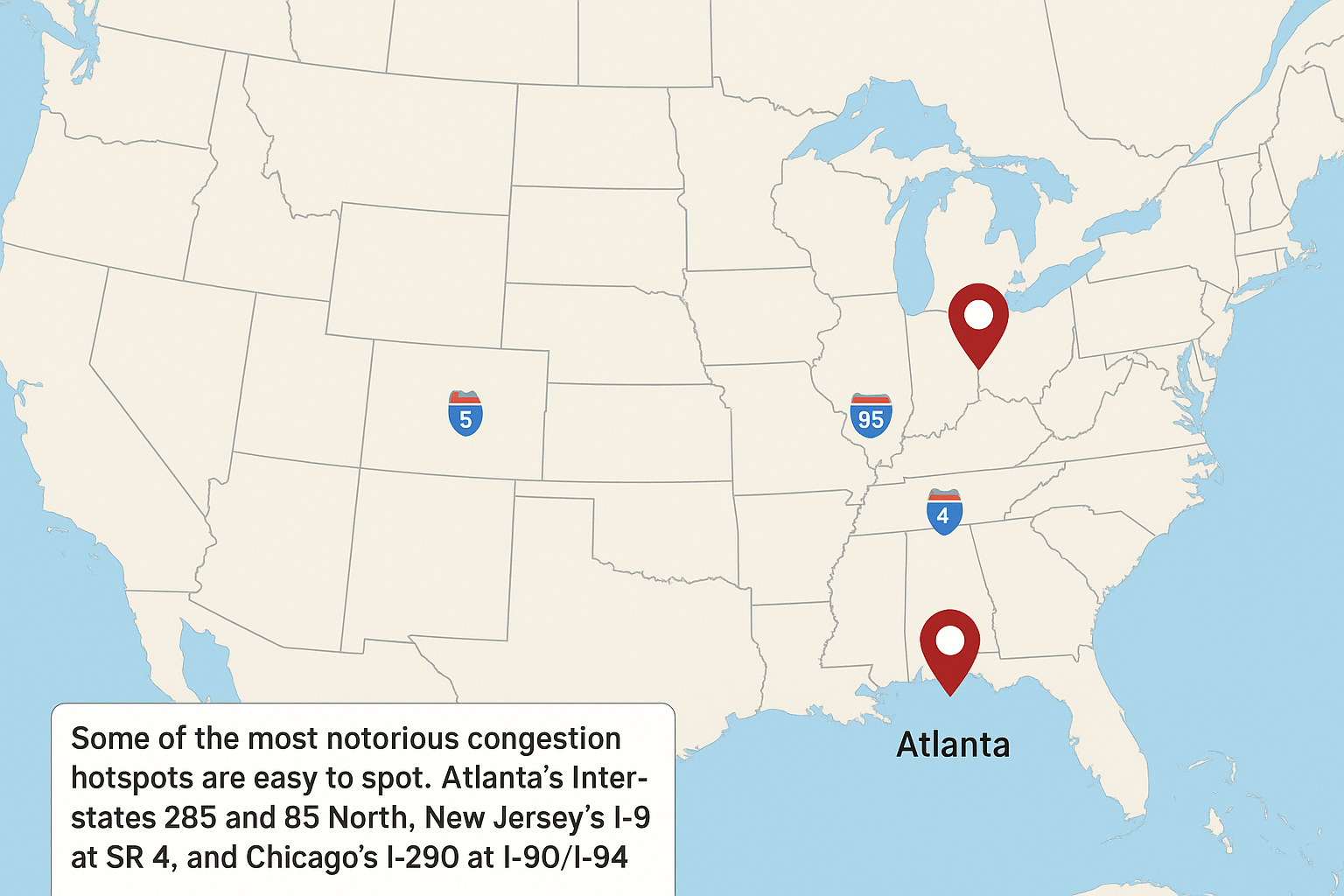

Some of the most notorious congestion hotspots are easy to spot. Atlanta’s Interstates 285 and 85 North, New Jersey’s I-95 at SR 4, and Chicago’s I-290 at I-90/I-94 rank among the busiest lanes in the country. Chicago alone lost $1.5 billion in 2014 due to traffic slowdowns, since 25% of the nation’s most congested highways run through the city.

What Are the Negative Impacts of Road Congestion?

Road congestion affects far more than just travel time—it hits budgets, schedules, and even people’s well-being. For trucking companies, traffic jams mean higher operational costs. Trucks burn more fuel when moving slowly or stopping and starting constantly. Drivers spend extra hours behind the wheel, which adds to labor costs. Every delay adds up, and those extra expenses often end up influencing the price of shipping services.

Delivery delays are another major concern. When a truck can’t move as planned, shipments arrive late. For small shippers using YK Freight, this can mean a vehicle shows up later than expected or a scheduled pick-up window is missed. Late deliveries frustrate customers, create complaints, and sometimes force shippers to pay more for expedited options just to make up lost time.

The human side of congestion is often overlooked. Drivers face stress from long hours and unpredictable traffic. Logistics managers scramble to reroute shipments or adjust schedules. Shippers worry about costs, deadlines, and keeping customers happy. Over time, this constant pressure can lower morale and efficiency throughout the supply chain.

Why Is It Hard to Forecast Shipping Deadlines During Congestion?

One of the biggest challenges in freight transportation is predicting exactly when a delivery will arrive. Highway congestion makes it nearly impossible to set precise deadlines. Traffic patterns can change suddenly—an accident, road construction, or even a small surge in vehicles can turn a smooth drive into a long, frustrating wait.

For example, imagine you’ve arranged a car shipment with YK Freight. Your vehicle is scheduled to arrive on Tuesday afternoon. But if the truck hits a congested highway near Atlanta or Chicago, it could be delayed by several hours—or even an entire day. These delays aren’t rare; they happen frequently on the busiest interstate routes.

For shippers on a budget, these delays can be costly. Extra hours on the road mean higher fuel costs, and sometimes additional charges may apply if delivery windows are missed. The frustration isn’t just financial—waiting for a vehicle that doesn’t arrive on time can disrupt personal plans or business schedules.

How Can Route Planning Reduce the Impact of Congestion?

One of the most effective ways to minimize the problems caused by highway congestion is smart route planning. By choosing the right roads and timing shipments carefully, shippers can avoid the worst traffic and keep deliveries on schedule.

Practical steps include route optimization, which uses software or logistics tools to calculate the fastest path, taking current traffic conditions into account. Avoiding peak traffic hours—like weekday mornings and evenings in busy cities—can also save hours of delay. Sometimes, alternative paths or less-congested highways may take slightly longer in distance but result in faster overall delivery because trucks aren’t stuck in stop-and-go traffic.

For budget-conscious shippers, this approach translates into real savings. Less time on the road means lower fuel costs, fewer driver hours, and fewer chances for missed deadlines. Working with a reliable logistics partner like YK Freight, you benefit from experienced route planning and real-time traffic monitoring, ensuring your vehicle reaches its destination efficiently without unnecessary extra costs.

Can Near-Shoring and Centralized Warehousing Help?

Another way to reduce the impact of highway congestion is by rethinking where goods are stored and shipped from. Near-shoring is a strategy where products or vehicles are sourced closer to their final destination, instead of traveling long distances from far-away locations. Shorter routes mean trucks spend less time on highways, reducing exposure to traffic jams and cutting fuel costs.

Cross-docking and centralized warehousing are additional tools to improve efficiency. With cross-docking, shipments are quickly transferred from one truck to another at a central facility without long-term storage. Centralized warehousing places goods in strategically located hubs close to major cities or customer clusters. Both methods allow shipments to reach destinations faster and with fewer miles on congested highways.

How Can Infrastructure and Multi-Modal Transportation Make a Difference?

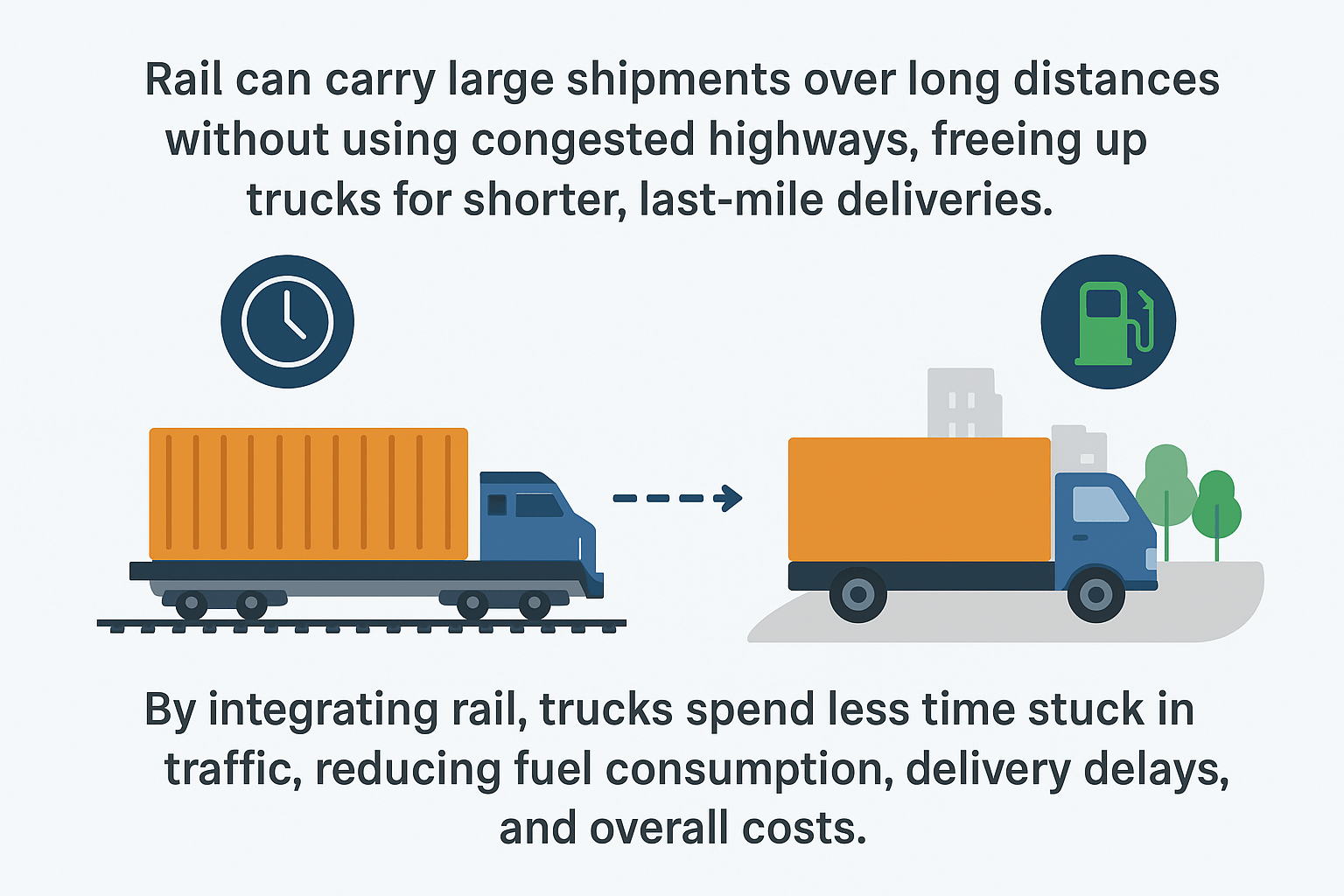

Highway congestion isn’t something that can be solved by trucking companies alone—government investment in infrastructure plays a critical role. Better-maintained highways, expanded lanes, and upgraded bridges can reduce bottlenecks and improve traffic flow. While this is a long-term solution, it benefits everyone in the supply chain, including shippers relying on services like YK Freight.

Another effective approach is multi-modal transportation. This means combining different types of transport, such as rail and road, to move goods more efficiently. Rail can carry large shipments over long distances without using congested highways, freeing up trucks for shorter, last-mile deliveries. By integrating rail, trucks spend less time stuck in traffic, reducing fuel consumption, delivery delays, and overall costs.

YK Freight leverages these multi-modal strategies to help budget-conscious shippers. For example, a vehicle might travel by rail for most of the journey, then be loaded onto a truck for final delivery. This approach not only avoids the worst highway congestion but also ensures shipments arrive faster and more reliably, while keeping shipping costs lower.

Further Reading:

How to Cut Costs on Last Mile Delivery: Smart Tips for Savings

How to Navigate the Driver Shortage: Tips for Faster, Affordable Auto Shipping

How Technology Is Changing Truck Drivers’ Lives and Improving Shipping Costs

The Future of Rail Freight Transportation: Safe, Efficient, and Cost-Effective

ASK YOUR QUESTIONS