Looking to transport goods efficiently without breaking the bank? This Dry Box Truck Complete Guide explains everything you need to know—what box trucks are, how to choose the right size, maintenance tips, and cost-saving strategies. Whether you’re delivering furniture, auto parts, or running a small business, this guide helps you make smart decisions and get the most value from your truck.

Table of Content:

- What Is a Dry Box Truck?

- What Are the Most Common Uses for Box Trucks?

- Why Choose a Box Truck Over Other Vehicles?

- How Do You Choose the Right Box Truck for Your Needs?

- How Can You Maintain a Box Truck for Longevity?

- What Are the Key Safety Practices for Box Truck Drivers?

- What Does the Future Hold for Box Trucks?

- Should You Buy or Rent a Box Truck?

What Is a Dry Box Truck?

A dry box truck, also known as a cube truck or straight truck, is a versatile medium-duty vehicle designed to transport goods safely and efficiently. Unlike semi-trucks, dry box trucks are self-contained—the cargo area is directly attached to the truck’s chassis, making them easier to drive, park, and maintain. They are a popular choice for small business owners, delivery services, and anyone who needs a reliable vehicle to move cargo without the complexity of larger tractor-trailers.

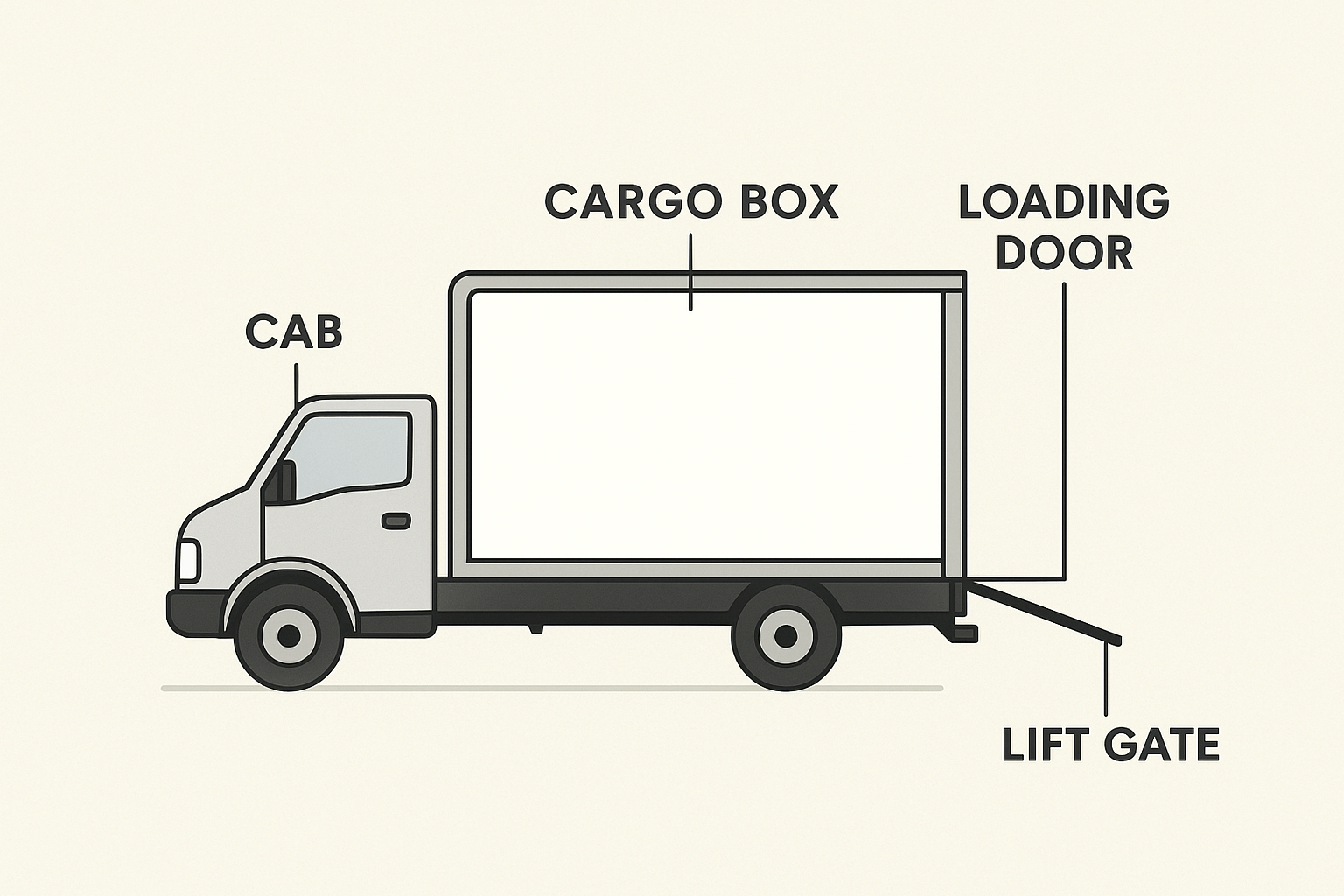

Key Components of a Dry Box Truck:

- Cab: This is the driver’s compartment, usually designed to seat 2–3 people. It’s the control center of the truck, featuring essential controls, seating, and sometimes additional storage.

- Cargo Box: The heart of the dry box truck. It’s a fully enclosed rectangular space, typically made of aluminum, fiberglass, or reinforced steel. This secure compartment protects your cargo from weather, theft, and damage during transport.

- Loading Door: At the back (and sometimes the side) of the cargo box, the loading door allows easy access for loading and unloading. Doors can be roll-up style, like a garage door, or swing doors, depending on the model.

- Lift Gate (Optional): For heavier items, many dry box trucks come with a hydraulic lift gate. This device lowers and raises cargo, saving time and effort while reducing the risk of injury or damage.

Sizes and Payloads:

Dry box trucks come in a range of sizes to suit different business needs:

- Length: Typically between 10 and 26 feet.

- Payload Capacity: Between 6,000 and 26,000 pounds, depending on the truck’s size and configuration.

For example, a 16-foot truck is ideal for moving furniture from a small apartment, while a 24-foot model can handle larger residential moves or multiple pallet deliveries.

Licensing Requirements:

The type of license you need depends on the Gross Vehicle Weight Rating (GVWR):

- Trucks under 26,000 lbs GVWR can usually be driven with a standard driver’s license in the U.S., making them accessible for small business owners or independent drivers.

- Trucks over 26,000 lbs GVWR typically require a commercial driver’s license (CDL), which involves additional testing and training.

What Are the Most Common Uses for Box Trucks?

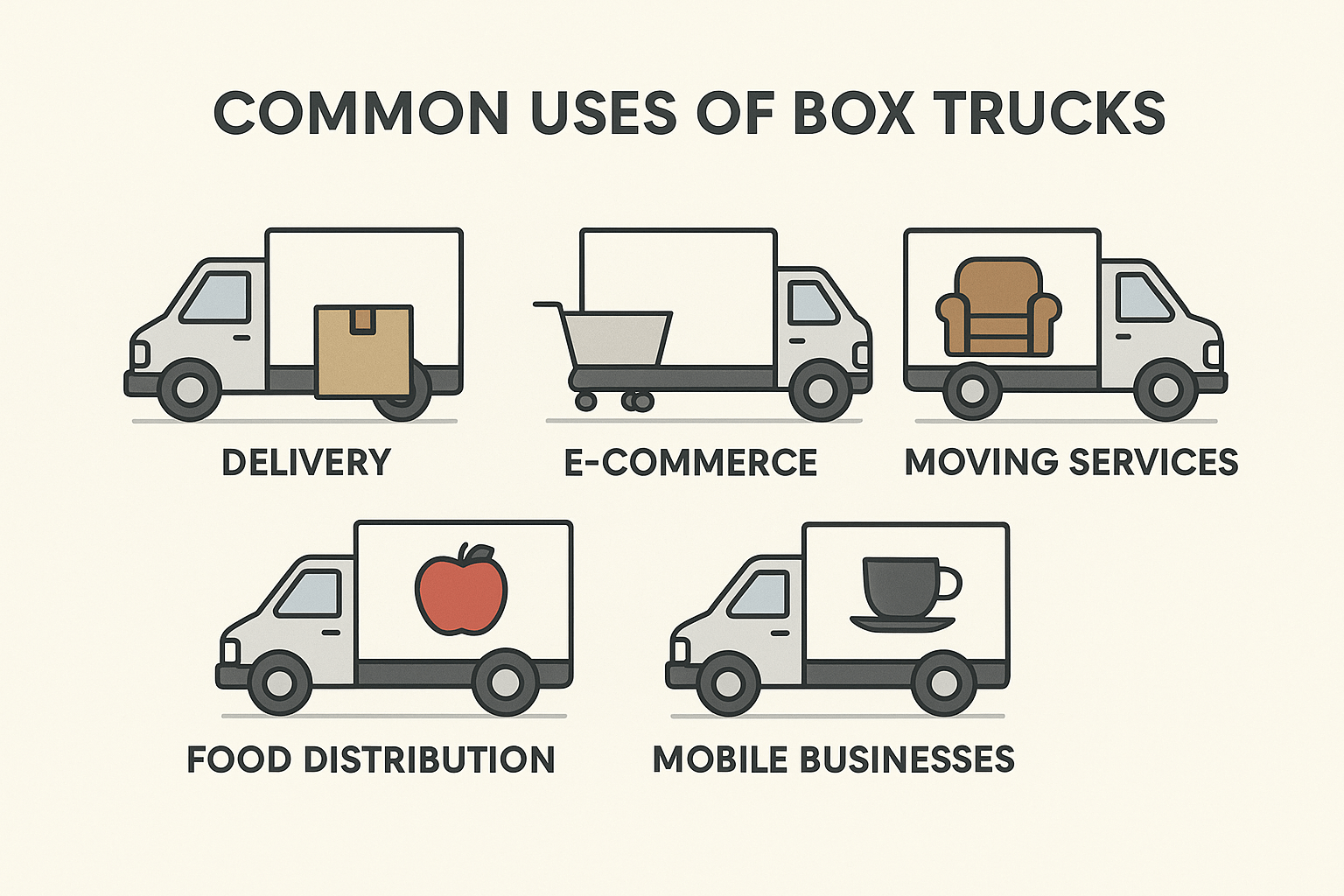

Dry box trucks are incredibly versatile, which is why they’re a favorite for small businesses and budget-conscious operators. Their enclosed cargo area keeps goods safe, while their size makes them easy to drive in urban streets or on regional routes. Here’s a breakdown of the most common ways people use box trucks:

1. Local and Regional Delivery

Box trucks are ideal for delivering furniture, appliances, and retail goods within a city or across nearby towns. For example, a local moving company might use a 16-foot truck to transport couches and tables between homes, while a small furniture store can deliver customer orders without hiring a large semi-truck. Companies like YK Freight often rely on box trucks for efficient short- to medium-distance deliveries because they balance cargo space with maneuverability.

2. E-Commerce and Last-Mile Deliveries

With the rise of online shopping, box trucks have become essential for last-mile delivery—getting packages from warehouses to customers’ doorsteps. If you run a small online store, a dry box truck can carry multiple orders in one trip, keeping items safe from rain, wind, or theft. Even independent couriers can use a truck of 12–18 feet to handle dozens of packages efficiently without incurring high vehicle costs.

3. Moving Services for Residential Customers

Small to mid-sized moving companies rely heavily on box trucks for residential moves. A 16- or 20-foot truck can easily handle a 1–3 bedroom apartment, making it perfect for budget-conscious movers or individuals helping friends and family relocate. The enclosed space ensures that furniture, electronics, and personal items remain protected throughout the move.

4. Retail and Food Distribution

Businesses delivering groceries, packaged foods, or temperature-sensitive goods benefit from refrigerated box trucks. For instance, a small bakery or local grocery store can use a refrigerated truck to distribute fresh products to nearby cafes or shops. Even on a tight budget, leasing or buying a used refrigerated box truck can help maintain product quality without investing in larger, costlier vehicles.

5. Mobile Businesses

Box trucks also serve as the foundation for mobile businesses. Entrepreneurs can convert them into food trucks, mobile retail shops, or mobile workshops. For example, a small coffee business can outfit a 14-foot truck with a counter, equipment, and storage, allowing it to serve customers at local events without the overhead of a permanent storefront.

Why Choose a Box Truck Over Other Vehicles?

If you’re trying to decide between a box truck, a cargo van, or a pickup, understanding the key differences can help you make a smart, budget-friendly choice. While vans and pickups work for smaller loads, box trucks offer unique advantages that make them ideal for small business owners, delivery drivers, and anyone looking to save money while moving larger items.

1. Space Efficiency

Box trucks are designed to maximize cargo space. Their rectangular, fully enclosed cargo area can hold pallets, stacked boxes, or large furniture that wouldn’t fit in a standard pickup bed. For example, a 16-foot box truck can transport the contents of a 2–3 bedroom apartment in one trip, while a pickup would require multiple runs. For small online store owners, this means fewer trips and lower fuel costs.

2. Security

The solid walls and lockable doors of a box truck provide better protection against theft and damage than open-bed pickups or cargo vans. Whether you’re delivering electronics, furniture, or auto parts, you can rest easy knowing your cargo is secure, even if you leave the truck parked during deliveries.

3. Weather Protection

Unlike pickups or open trailers, box trucks keep your cargo dry and clean. Rain, snow, or dust won’t damage boxes or equipment, which is especially important for businesses handling sensitive or perishable items. For example, someone transporting groceries, electronics, or small machinery can avoid costly weather-related losses.

4. Cost-Effectiveness

Box trucks often offer lower operational costs than larger semi-trucks while carrying more than a van or pickup. Their fuel consumption is reasonable for short- and medium-distance deliveries, and maintenance costs are typically lower than those for tractor-trailers. For a small delivery business, using a 16–18 foot box truck instead of a larger truck can save hundreds of dollars per month in fuel and upkeep.

5. Accessibility

Many box trucks don’t require a commercial driver’s license (CDL) if they fall under the 26,000 lbs GVWR limit. This accessibility makes them perfect for budget-conscious operators or small business owners who want a professional-grade vehicle without investing in CDL training. For instance, an independent courier or someone starting a moving service can legally operate a box truck with a standard driver’s license, unlike larger semi-trucks that require additional licensing.

How Do You Choose the Right Box Truck for Your Needs?

Choosing the right box truck is crucial, especially if you’re budget-conscious and want to get the most value out of your investment. The right truck can save you money on fuel, maintenance, and trips while making your deliveries more efficient. Here’s a step-by-step guide to help you make an informed decision:

1. Size and Payload

The first step is to match the truck’s cargo volume and payload capacity to your typical loads. Box trucks range from 10 to 26 feet in length:

- A 12–16 foot truck works well for local deliveries or moving a small apartment.

- A 20–26 foot truck is better for larger residential moves or transporting multiple pallets at once.

Payload matters too—make sure the truck can safely carry your heaviest items without exceeding its GVWR. For example, someone delivering cars or auto parts may need a truck that can handle up to 12,000 lbs, while a furniture delivery service might prioritize cargo volume over maximum weight.

2. Fuel Type

Choosing between diesel and gasoline depends on your delivery patterns:

- Diesel: More fuel-efficient for longer routes and heavier loads. Offers better torque, which is helpful when hauling full pallets or heavy furniture. Diesel trucks may cost more upfront but save money on fuel over time.

- Gasoline: Cheaper to buy and maintain for short, local routes. Ideal for small businesses that mostly operate within a city or town.

3. New vs. Used

- New Trucks: Come with warranties, modern safety features, and less risk of breakdowns. If you plan to use the truck daily, a new model could be a smart long-term investment.

- Used Trucks: More affordable upfront, which is great if you’re on a tight budget. However, used trucks may need inspections to check for engine wear, transmission issues, or rust. For example, a small delivery business could buy a well-maintained used 16-foot truck and save thousands compared to a new one, while still handling most deliveries efficiently.

4. Special Features

Consider features that make your work easier:

- Lift Gate: Essential if you frequently handle heavy or bulky items like appliances or machinery.

- Refrigeration: Necessary for perishable goods such as groceries, food products, or pharmaceuticals.

- Shelving/Storage: Customizable interiors can help organize smaller items, making loading and unloading faster.

Even a budget-conscious buyer can prioritize one or two key features that directly improve efficiency without overspending.

5. Budget and Financing

Factor in total ownership costs, not just the purchase price:

- Insurance and registration vary based on truck size and usage.

- Maintenance and fuel costs affect long-term affordability.

- Leasing options can be a good choice for seasonal businesses or those with fluctuating delivery needs, allowing access to newer trucks without the large upfront cost.

Practical Example:

Imagine you run a small online auto parts store. A 16-foot used gasoline box truck with a lift gate could carry multiple shipments per trip, protect your items from weather, and save on fuel and licensing costs compared to a diesel or larger truck. For someone helping customers move apartments, a 20-foot truck with shelving and a lift gate might be worth leasing for peak moving season to avoid paying for a full-year purchase.

How Can You Maintain a Box Truck for Longevity?

Keeping your box truck in top shape doesn’t have to be complicated or expensive. Regular maintenance ensures your truck runs reliably, protects your cargo, and helps you avoid costly repairs down the road. Here are practical, budget-friendly tips for long-term care:

1. Engine Care

The engine is the heart of your truck, and taking care of it saves money in the long run.

- Oil Changes: Follow the manufacturer’s schedule—typically every 5,000–7,000 miles for diesel and 3,000–5,000 miles for gasoline. Fresh oil keeps the engine lubricated and prevents wear.

- Coolant Checks: Monitor coolant levels to avoid overheating, especially during long trips.

- Air and Fuel Filters: Replace filters regularly to maintain engine efficiency and reduce fuel consumption.

2. Tire Maintenance

Tires are critical for safety and fuel efficiency.

- Rotation: Rotate tires every 6,000–8,000 miles to ensure even wear.

- Pressure Checks: Properly inflated tires reduce blowouts and improve gas mileage, saving money at the pump.

3. Brake Inspections

Brakes are essential for safety, particularly when carrying heavy loads.

- Regular Checks: Inspect brake pads, rotors, and fluid levels at least once a year.

- Early Replacement: Replacing worn pads early prevents damage to the rotors, which can be much more expensive.

4. Cargo Area Upkeep

Your cargo box is what makes a box truck special, so keep it in good condition.

- Clean Spills Promptly: Any liquids or debris should be removed immediately to prevent corrosion or stains.

- Lubricate Doors and Hinges: Smooth-running roll-up or swing doors reduce wear and prevent costly repairs.

5. Electrical System Checks

Electrical problems can ground your truck and delay deliveries.

- Batteries and Alternators: Test them regularly to avoid unexpected breakdowns.

- Lighting System: Check brake lights, turn signals, and interior cargo lighting to stay safe and comply with regulations.

Cost-Saving Benefits:

Routine maintenance might feel like extra work, but it prevents major repairs that can cost thousands of dollars. For example, regularly checking tires and brakes avoids blowouts or brake failures, which could lead to accidents or downtime. Maintaining the engine and electrical systems keeps fuel consumption low and extends the life of your truck.

What Are the Key Safety Practices for Box Truck Drivers?

Driving a box truck comes with responsibilities that go beyond just reaching your destination. Because these trucks are larger than regular vehicles and often carry heavy or bulky loads, safety is essential for protecting yourself, your cargo, and others on the road. Here are practical tips for small business owners and independent drivers:

1. Secure Loads Properly

Loose or shifting cargo is one of the leading causes of accidents and damage.

- Use Straps, Nets, or Load Bars: Always tie down items, especially heavy or stacked loads, to prevent them from moving while driving.

- Distribute Weight Evenly: Place heavier items on the bottom and near the truck’s center to maintain stability.

For example, a small moving company delivering furniture can avoid damage to couches and appliances by securing everything tightly before hitting the road.

2. Monitor Blind Spots

Box trucks have larger blind spots than regular cars, increasing the risk of collisions.

- Convex Mirrors: Install mirrors that provide a wider field of view around the truck.

- Cameras: Backup and side cameras can alert you to pedestrians, cyclists, or vehicles in hard-to-see areas.

Independent delivery drivers can use these tools to navigate crowded urban streets safely, avoiding minor accidents that can be costly for a small business.

3. Adjust Speed for Conditions

A box truck’s handling changes depending on load and weather.

- Reduce Speed in Bad Weather: Rain, snow, or ice can make braking distances much longer.

- Consider Cargo Weight: Heavier loads require slower turns and longer braking distances.

For instance, when delivering a full load of auto parts in winter, slowing down by even 5–10 mph can prevent accidents and save money on potential repairs.

4. Driver Training and Defensive Driving

Education and awareness are key to safe operations.

- Defensive Driving: Always anticipate other drivers’ actions, maintain safe following distances, and avoid distractions.

- Emergency Protocols: Know how to handle skids, tire blowouts, or sudden stops safely.

Small business owners should invest time in training themselves and their employees, which reduces accidents, insurance claims, and downtime.

What Does the Future Hold for Box Trucks?

The box truck industry is evolving fast, and staying informed about emerging trends can help small business owners and budget-conscious operators make smart, long-term decisions. From electric powertrains to autonomous technology and telematics, these innovations are shaping the way goods are transported efficiently and affordably.

1. Electric Box Trucks

Electric box trucks are becoming more common, with models like the Ford E-Transit and Mercedes eSprinter hitting the market.

- Cost Savings: Electric trucks reduce spending on fuel and often have lower maintenance costs since they have fewer moving parts than diesel engines.

- Environmental Benefits: Zero-emission trucks help businesses comply with sustainability goals and can reduce city tolls or access fees in some areas.

For a small delivery business, investing in a smaller electric box truck can cut monthly fuel costs significantly, especially for local or urban routes, while future-proofing the fleet.

2. Autonomous Trucking Developments

Self-driving technology is starting to appear in the box truck sector. Companies like TuSimple are testing autonomous trucks for highway logistics, which may one day reduce the need for human drivers on long routes.

- Efficiency Gains: Autonomous systems could optimize driving patterns, reduce delays, and lower accident risks.

- Cost Considerations: While fully autonomous trucks aren’t widely available yet, staying aware of developments helps operators plan for future upgrades or partnerships.

For small businesses, this means potential long-term savings on labor and insurance costs once the technology becomes mainstream.

3. Telematics: GPS and IoT Sensors

Modern box trucks increasingly use telematics—systems that track vehicle location, cargo conditions, and driver behavior.

- Route Optimization: GPS technology can help drivers take the fastest, most fuel-efficient routes.

- Cargo Monitoring: IoT sensors alert operators to temperature changes, shocks, or tampering, protecting valuable goods.

- Preventive Maintenance: Telematics can detect early signs of mechanical issues, reducing repair costs and downtime.

Budget-conscious operators can benefit immediately from these tools, improving efficiency without upgrading to a brand-new truck.

Should You Buy or Rent a Box Truck?

Deciding whether to buy or rent a box truck depends on your business needs, budget, and how frequently you plan to use the vehicle. Both options have advantages, and understanding them can help small business owners and independent operators make cost-effective decisions.

1. Buying a Box Truck

Buying is ideal if you plan to use the truck daily or as a core part of your business.

- Long-Term Savings: Owning a truck outright can save money over time compared to repeated rental fees.

- Customization and Branding: You can add shelves, refrigeration units, lift gates, or even your business logo for mobile advertising.

- Reliability: Having your own truck ensures it’s always available when you need it, which is crucial for regular deliveries or moving services.

Example: A small auto parts delivery business using a 16-foot box truck daily can purchase a truck through YK Freight to ensure consistent service while customizing the cargo area to handle various parts efficiently.

2. Renting a Box Truck

Renting works well for seasonal demand, short-term projects, or one-time moves.

- Lower Upfront Cost: You avoid the large initial investment and can use the truck only when needed.

- Flexible Options: Rental companies often provide trucks of different sizes and features depending on the project.

- Maintenance-Free: Most rentals include basic maintenance, saving you time and money on repairs.

Example: A small moving business might rent a 20-foot truck for busy summer months when demand spikes, then return it during slower periods, saving on storage and maintenance costs. Companies like YK Freight offer guidance and flexible rental rates to help operators choose the right size and duration for their needs.

ASK YOUR QUESTIONS