Managing inbound freight efficiently can save your business time and money. This guide breaks down simple, practical strategies to improve shipments from suppliers, reduce hidden costs, and strengthen supplier relationships. Whether you’re a small auto dealer or a budget-conscious business, these best practices show how to gain control, increase visibility, and make every inbound shipment work smarter for you.

Table of Content:

- What Is Inbound Freight Management and Why Does It Matter?

- How Can You Evaluate Your Current Inbound Freight Strategy?

- Why Is Vendor Compliance So Important?

- How Does Inventory Control Improve Inbound Efficiency?

- What Role Does Visibility Play in Cutting Costs?

- How Can Better Communication Strengthen Supplier Relationships?

- What Are Simple Steps to Start Improving Your Inbound Freight Today?

- How Can a Reevaluation of Your Strategy Save You Money Long-Term?

What Is Inbound Freight Management and Why Does It Matter?

Inbound freight refers to all shipments coming from your suppliers, vendors, or manufacturers to your business. In simple terms, it’s the flow of materials, parts, or finished goods that you need to keep your operations running. Whether you’re a small car dealer waiting for vehicles or a parts distributor restocking your warehouse, these incoming shipments are what keep your business moving.

However, many companies don’t pay enough attention to inbound freight. They tend to focus on outbound logistics — the process of getting goods to customers — while forgetting that incoming shipments can eat up a huge part of their transportation budget. In fact, inbound freight can account for as much as 40% of total logistics costs. That’s a big number, especially for businesses that are already working with tight budgets.

Poor inbound management often leads to hidden expenses like delayed deliveries, overstocking, missed supplier deadlines, and unnecessary rush shipments. These issues might not seem major at first, but they quickly add up and reduce profit margins.

That’s why inbound freight management matters. It’s about gaining control and visibility over how goods arrive at your facility — knowing when they’re shipped, how they’re transported, and how much they truly cost you. When managed properly, inbound freight can help you cut costs, improve efficiency, and strengthen your relationships with suppliers.

How Can You Evaluate Your Current Inbound Freight Strategy?

Before making any changes or investing in new tools, it’s smart to take a step back and analyze what’s already happening in your inbound process. Many companies jump into trying to “fix” things without really knowing where the problems are — and that often leads to wasted effort and money. A simple review can reveal hidden inefficiencies that quietly raise your costs.

Start by asking a few key questions:

- Are your vendors following your delivery and packaging requirements?

- Do you have real-time visibility into where your shipments are?

- How often do you deal with late deliveries or damaged goods?

- Do you know exactly how much you’re spending on inbound transportation?

For example, imagine a small auto dealer who orders used cars from several suppliers. Each supplier handles shipping differently — one sends vehicles on time, another always runs late, and a third often adds “extra” transport fees. The dealer doesn’t have a clear system to track these details, so every month, they lose money without realizing it. By reviewing their inbound process, the dealer could identify which suppliers are reliable and which are causing unnecessary costs.

Evaluating your current strategy helps you see where your money is really going. It’s not just about pointing out what’s wrong — it’s about finding areas where better coordination or clearer agreements could save you time and resources.

Why Is Vendor Compliance So Important?

Vendor compliance is one of the key building blocks of effective inbound freight management. It simply means that your suppliers follow the rules and standards you’ve set for shipping — such as delivery schedules, packaging methods, labeling, and documentation. When vendors stick to these requirements, your operations run smoothly. When they don’t, you face delays, damaged goods, and surprise costs that can easily throw off your budget.

For example, imagine you run a small dealership and expect a shipment of vehicles to arrive on Wednesday. The supplier, however, sends them late without notice — or worse, ships them to the wrong facility. Suddenly, your sales appointments are delayed, you’re paying for unexpected storage or redelivery fees, and your schedule is off balance. These are the kinds of problems vendor compliance helps prevent.

Clear agreements with your suppliers set expectations from the start. They should outline delivery timelines, packaging and handling standards, insurance coverage, and the type of documentation needed for every shipment. With these details in place, you eliminate confusion and ensure everyone understands their responsibilities.

At YK Freight, we help businesses strengthen vendor compliance by setting up clear inbound shipping requirements and communication systems. For instance, our clients receive standardized shipping guidelines that their suppliers must follow before pickup or delivery. This includes consistent labeling, verified shipment data, and proof of delivery. When all parties follow the same playbook, it becomes easier to track shipments, avoid costly errors, and maintain smooth logistics operations.

How Does Inventory Control Improve Inbound Efficiency?

Inventory control plays a major role in how efficiently your inbound freight process runs. When you know exactly what’s coming in, when it’s arriving, and how much stock you already have, you can plan ahead and avoid costly mistakes. Without that control, it’s easy to fall into problems like overstocking, paying for extra storage, or making expensive last-minute delivery requests.

For example, imagine a small auto parts business that orders components from several suppliers. Without proper tracking, they might reorder items they already have in stock — simply because no one realized a shipment was already on the way. As a result, the warehouse fills up, inventory sits unused, and cash gets tied up in unnecessary stock. On the other hand, if they suddenly run out of critical parts and need to restock fast, they may have to pay premium rates for urgent delivery. Both situations waste money that could’ve been saved with better inventory oversight.

When inbound shipments are monitored closely, businesses can adjust purchase orders, plan storage space, and time deliveries more efficiently. Real-time tracking also helps prevent production slowdowns or missed customer deadlines by ensuring that the right products arrive at the right time.

At YK Freight, we help clients improve inventory control by giving them better visibility over their inbound shipments. With access to shipment tracking tools and data reports, businesses can monitor every delivery in transit — whether it’s a truckload of vehicles or smaller parts moving between facilities. This level of control helps them plan ahead, reduce

What Role Does Visibility Play in Cutting Costs?

Visibility is one of the most powerful tools for saving money in inbound freight management. When you have clear insight into where your shipments are, how they’re moving, and when they’ll arrive, you can make smarter decisions — and avoid expensive surprises. Without visibility, small issues like delays, lost paperwork, or routing mistakes can go unnoticed until they turn into real problems that drain your budget.

Think of visibility as having a window into your supply chain. You can spot when a supplier is running behind schedule, when a truck is stuck in transit, or when a shipment is about to arrive early. This allows you to react before those events cause disruptions. For instance, a small car importer who tracks incoming shipments in real time can reschedule offloading teams or adjust storage space ahead of time — instead of paying for last-minute labor or extra holding costs.

![]()

Better visibility also means better control. You can track supplier performance, compare planned vs. actual delivery times, and identify which routes or carriers are the most efficient. Over time, this data helps you optimize your logistics strategy and spend less on transportation overall.

At YK Freight, we make visibility simple and affordable. Our technology solutions — from real-time tracking systems to easy-to-use data dashboards — help clients see the full picture of their inbound freight without overspending on complex software. Even businesses with limited budgets can monitor their shipments, receive instant updates, and analyze key performance metrics in one place.

How Can Better Communication Strengthen Supplier Relationships?

Strong communication with your suppliers is one of the simplest and most effective ways to improve inbound freight management. When everyone involved — from vendors to carriers — clearly understands schedules, requirements, and expectations, you reduce the chances of misunderstandings, delivery errors, and costly penalties.

Many shipping issues start with poor communication. For example, a buyer might assume a supplier will handle transport costs, while the supplier expects the buyer to pay upon delivery. The result? Unexpected fees, delayed shipments, and frustration on both sides. A quick conversation or shared shipment plan could have prevented it.

When businesses and suppliers share information openly — such as delivery timelines, tracking data, and inventory needs — it becomes easier to plan ahead. Everyone knows what to expect, and problems can be solved before they grow into expensive mistakes. This kind of transparency also helps build trust, turning supplier relationships into long-term partnerships rather than one-time transactions.

Imagine a small auto dealer working with several car suppliers. By setting up a regular communication schedule — say, weekly shipment updates or shared dashboards — the dealer can see which vehicles are in transit and which are delayed. If there’s a sudden route change or weather delay, both sides can react quickly, avoiding surprise storage or delivery fees.

At YK Freight, we help clients strengthen supplier communication through integrated systems that keep all shipping data in one place. Our platform allows businesses and suppliers to share updates, confirm shipment details, and monitor delivery progress in real time. This reduces back-and-forth confusion and helps everyone stay aligned.

What Are Simple Steps to Start Improving Your Inbound Freight Today?

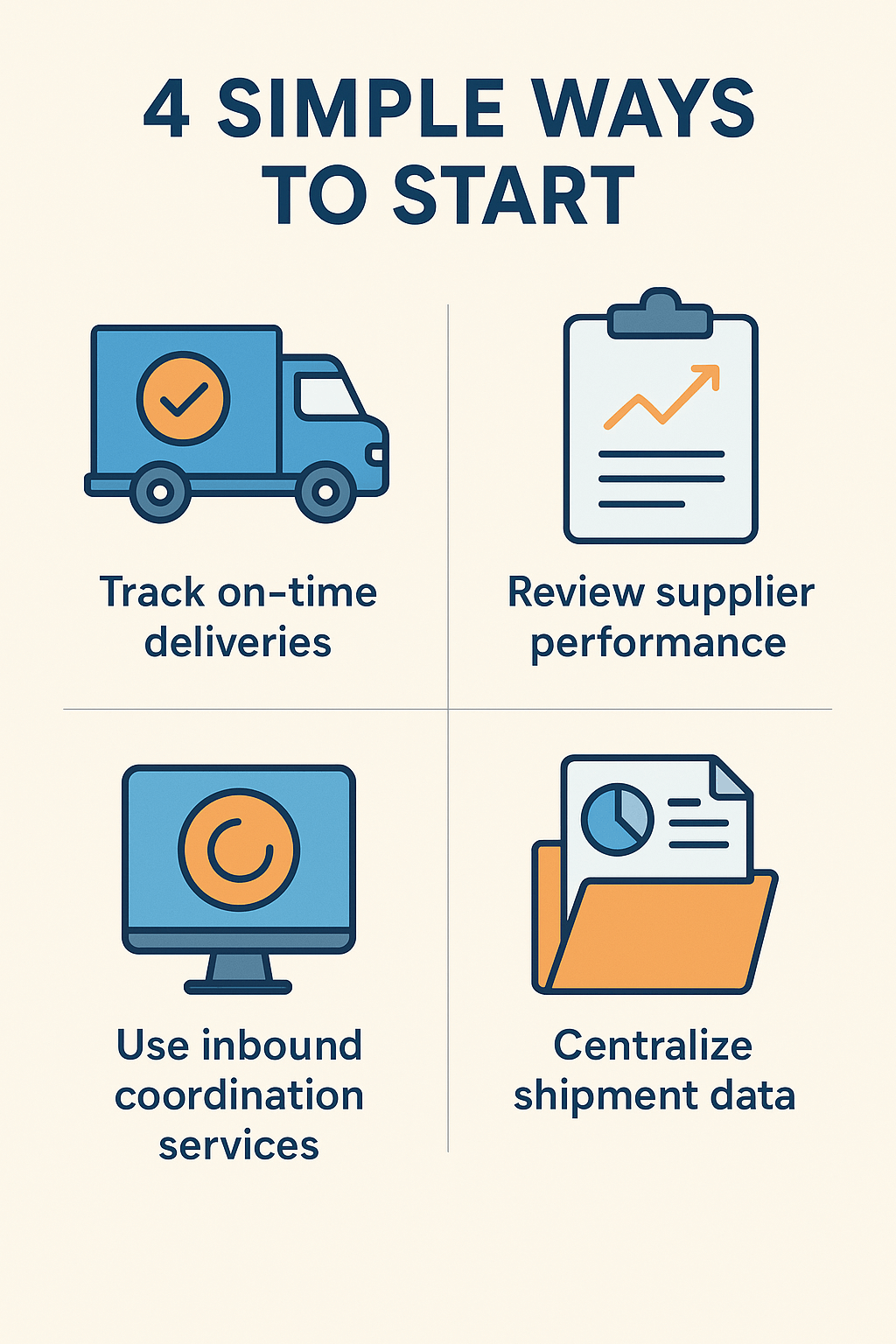

Improving your inbound freight process doesn’t have to mean a full overhaul or major investment. In fact, small, consistent actions can lead to noticeable savings over time. The key is to focus on the areas you can control right now and build better habits step by step. Here are a few simple ways to start.

1. Track on-time deliveries

Keep a record of how often your suppliers deliver shipments on schedule. This doesn’t just help you identify who’s reliable — it also highlights patterns of delay that may be costing you money. For example, if one supplier is consistently late, you can discuss penalties, adjust order times, or explore alternative options. A clear delivery log keeps everyone accountable and helps you plan more accurately.

2. Review supplier performance quarterly

Set aside time every few months to evaluate how your suppliers are performing. Look at factors such as delivery speed, communication, packaging quality, and compliance with your requirements. This gives you a chance to recognize strong partners and address weak points before they lead to bigger problems. Over time, this regular review process helps you build a dependable, cost-efficient supply network.

3. Use YK Freight’s inbound coordination services

Coordinating inbound shipments can get complicated — especially when you’re working with multiple suppliers or transport modes. YK Freight can simplify this process for you by handling scheduling, communication, and shipment tracking in one place. Our team ensures every delivery runs smoothly, reducing delays and unnecessary expenses. For businesses with limited budgets, having an experienced logistics partner means getting professional results without overspending.

4. Centralize shipment data in one system

Scattered spreadsheets, email threads, and paper records make it hard to manage your inbound logistics efficiently. By keeping all shipment information in one platform — such as YK Freight’s digital dashboard — you can quickly check statuses, compare costs, and make informed decisions. Centralized data improves visibility and saves valuable time that would otherwise be spent chasing updates.

How Can a Reevaluation of Your Strategy Save You Money Long-Term?

Inbound freight management isn’t something you set once and forget. The market changes, fuel prices fluctuate, and supplier conditions evolve — all of which can affect your transportation costs. That’s why it’s important to regularly reassess your inbound processes and make adjustments where needed. A simple reevaluation can uncover inefficiencies that quietly drain your budget and help you discover new ways to save.

The goal isn’t to rebuild your entire logistics system overnight. Instead, focus on gradual, realistic improvements that align with your business size and resources. For instance, you might start by reviewing how your suppliers handle delivery schedules, then move on to tightening inventory control or improving shipment tracking. Even small upgrades — like adjusting routes or setting clearer vendor expectations — can generate steady long-term savings.

Regular evaluation also helps prevent your inbound strategy from becoming outdated. Many companies lose money simply because they continue using the same methods year after year without checking if those methods still work. By staying proactive, you can spot changes in shipping patterns early, renegotiate supplier terms, and take advantage of more efficient delivery options.

At YK Freight, we help businesses go through this process step by step. Our team analyzes inbound data, identifies unnecessary expenses, and offers practical recommendations tailored to your budget. Whether it’s optimizing freight routes, improving vendor compliance, or introducing better visibility tools, we make sure every adjustment contributes to your long-term savings goals.

Further Reading:

Frequently Asked Questions About Container Drayage

What is 3PL Experience? Benefits of Third-Party Logistics

ASK YOUR QUESTIONS