Effective vendor management can make or break your shipping budget. Poor coordination leads to delays, hidden fees, and extra costs, especially for vehicle shipments. This guide highlights three best practices — compliance programs, high visibility, and expert logistics partnerships — to help budget-conscious shippers control costs, streamline deliveries, and avoid common mistakes.

Table of Content:

- Why Is Vendor Management So Important for Inbound Shipping Costs?

- What Problems Do Companies Face Without Proper Vendor Control?

- What Is a Vendor Compliance Program and Why Does It Matter?

- How Does a Vendor Compliance Program Reduce Costs and Errors?

- Why Is High Visibility Critical for Managing Vendors Effectively?

- How Can Data and Tracking Tools Improve Vendor Performance?

- Why Can’t Most Vendors Optimize Shipping on Their Own?

- How Does Partnering With a 3PL Improve Vendor Management?

- How Does Working With YK Freight Help Control Vendor-Related Costs?

- What Practical Vendor Management Mistakes Should Budget Shippers Avoid?

- How Can Better Vendor Management Lead to Long-Term Savings?

Why Is Vendor Management So Important for Inbound Shipping Costs?

Inbound shipping is the first step of the entire supply chain. If something goes wrong here, every next step becomes more expensive. For companies and individuals shipping vehicles on a budget, poor vendor management is one of the main reasons freight costs end up much higher than expected.

The biggest issue is lack of control. When vendors handle pickup, documentation, routing, and delivery without clear rules, small problems turn into costly ones. A missed pickup window leads to storage fees. Wrong paperwork causes port delays. Poor coordination results in rebooking and extra handling charges.

Another major problem is lack of visibility. If you don’t know where your shipment is or what stage it’s in, you can’t react in time. Delays go unnoticed until it’s too late. At that point, you’re paying for demurrage, storage, or urgent fixes that could have been avoided.

In real numbers, inbound shipments with poor visibility can consume up to 40% of total freight costs. These are not planned expenses. They come from:

- Unexpected storage fees

- Extra handling at ports

- Missed sailings and rebookings

- Last-minute routing changes

For a budget-focused vehicle shipper, this feels familiar. The quote looked affordable, but the final bill was much higher. Not because the distance changed — but because vendor actions weren’t properly managed.

Good vendor management puts structure and accountability in place. It ensures everyone knows their role, timelines are respected, and issues are spotted early. When inbound shipping is controlled, costs stay predictable, delays drop, and budgets stop breaking.

What Problems Do Companies Face Without Proper Vendor Control?

When vendors are not properly managed, problems appear fast — and they almost always lead to higher costs. For budget-conscious customers shipping vehicles, these issues feel very familiar because they show up as surprise charges and frustrating delays.

One of the most common problems is delivery delays. A vendor misses a pickup window or submits paperwork late. The vehicle arrives at the port after the cutoff time and misses the scheduled vessel. That single mistake can add storage fees, rebooking costs, and weeks of delay.

Another major issue is hidden fees. Without clear vendor rules, extra charges often appear after the shipment has already started. These can include:

- Unexpected storage or yard fees

- Additional handling charges

- Documentation corrections

- Last-minute route changes

At that point, the shipper has little choice but to pay.

Miscommunication makes everything worse. One vendor assumes another is handling a task. No one confirms responsibility. The result is confusion, delays, and finger-pointing — while the customer absorbs the cost.

There is also the risk of damaged goods. Poorly managed vendors may rush loading, skip inspections, or use improper equipment. For vehicle shipping, this can mean scratches, dents, or mechanical issues that lead to repair costs and insurance claims.

All these problems lead to real budget losses:

- Higher final shipping bills

- Longer delivery times

- Missed sales or deadlines

- Loss of trust in the shipping process

Customer dissatisfaction follows quickly. When costs rise and timelines slip, people feel misled — even if the original quote was accurate.

What Is a Vendor Compliance Program and Why Does It Matter?

A vendor compliance program is a clear, written set of rules that defines how vendors must handle shipments. It outlines what is expected, who is responsible, and what happens if rules are not followed. For companies and individuals shipping vehicles on a budget, this structure is essential for controlling costs.

Without a compliance program, vendor relationships often rely on assumptions. One side thinks a service is included. The other thinks it’s extra. This is how disputes and surprise fees start. A vendor compliance program removes guesswork by setting predefined terms from the beginning.

These programs usually cover:

- Pickup and delivery timelines

- Required documentation

- Packaging and handling standards

- Approved routes and ports

- Penalties for delays or errors

The key benefit is accountability. Vendors know they are responsible for meeting performance standards. If they fail — for example, by missing a pickup or submitting incorrect paperwork — the financial impact does not automatically fall on the shipper.

For budget-focused vehicle shippers, this matters a lot. One vendor mistake can easily add hundreds of dollars in storage or rebooking fees. A compliance program helps recover those costs or prevent them altogether.

Another important point is that these programs are non-negotiable once implemented. While both sides agree on the terms during setup, the rules apply consistently afterward. This creates fair and predictable cooperation instead of constant renegotiation.

How Does a Vendor Compliance Program Reduce Costs and Errors?

A vendor compliance program works because it sets clear performance rules and real consequences. When vendors know exactly what is expected — and what happens if they fail — errors drop and costs stay under control.

The first way it reduces costs is by preventing failed deliveries. Performance requirements define strict timelines for pickup, documentation, and port arrival. Vendors are less likely to miss deadlines when they know delays will trigger penalties. This helps avoid missed sailings, rebooking fees, and extra storage costs.

Second, it cuts down on unnecessary charges. Without compliance rules, vendors may choose cheaper but inefficient routes, submit incorrect paperwork, or delay communication. Each of these mistakes adds cost. A compliance program forces vendors to follow approved processes, which reduces corrections and last-minute fixes.

Another key benefit is cost recovery. When a vendor causes a problem — for example, a late delivery that results in port storage fees — the compliance program allows the shipper to recover part or all of that cost. Instead of the customer paying for someone else’s mistake, responsibility is clearly assigned.

Risk reduction is also critical. For vehicle shipping, risks include damage, delays, and compliance violations. Vendor compliance programs require proper handling standards and documentation, lowering the chance of accidents or customs issues that can lead to costly claims.

For budget-focused shippers, the result is simple:

- Fewer surprises on the final invoice

- More predictable delivery timelines

- Lower exposure to unexpected risks

Why Is High Visibility Critical for Managing Vendors Effectively?

High visibility means knowing where your shipment is, what stage it’s in, and who is responsible at every moment. Without this visibility, vendor management becomes guesswork — and guesswork almost always leads to delays and hidden costs.

When shipments aren’t tracked closely, problems stay invisible until they become expensive. A vendor misses a pickup window, but no one notices. Paperwork is incomplete, but the issue is discovered only when the cargo reaches the port. By then, it’s too late to fix things cheaply.

This lack of visibility causes common and costly problems:

- Missed sailings due to late arrival

- Unexpected storage or demurrage fees

- Emergency rebooking at higher rates

- Last-minute paperwork corrections

For inbound shipping, these costs add up fast. Many budget-focused shippers recognize this situation: the delivery quote looked fine, but the final bill is much higher because delays were caught too late.

Another mistake is focusing only on final delivery tracking. Many companies track shipments only after they leave the port. But inbound shipments — pickup, inland transport, port arrival, and documentation — are just as important. Most avoidable costs happen before the cargo ever gets on a vessel.

Effective vendor management requires visibility from the very beginning:

- Is the vendor on schedule for pickup?

- Has documentation been submitted correctly?

- Has the shipment reached the port on time?

When this information is available in real time, issues can be fixed early, when solutions are still affordable.

How Can Data and Tracking Tools Improve Vendor Performance?

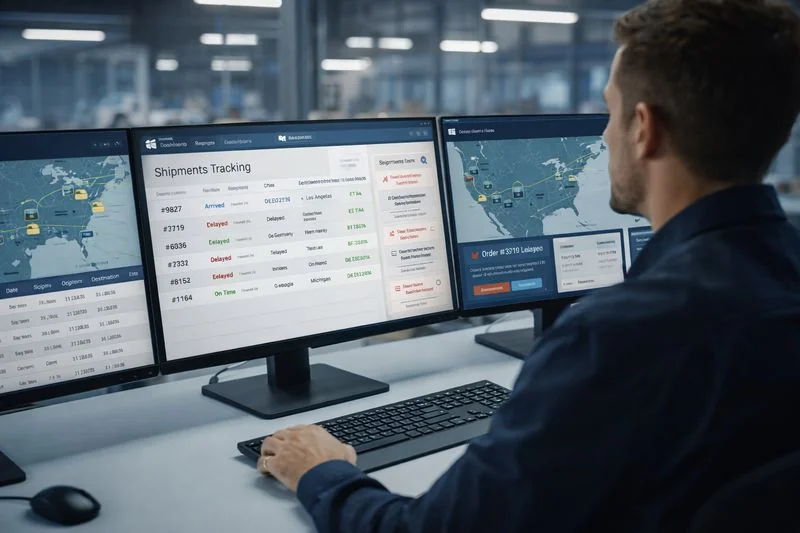

Data and tracking tools turn vendor management from reactive to controlled. Instead of guessing why costs are rising, shippers can see exactly where problems start and fix them early.

The most common tool for this is a transportation management system (TMS). A TMS tracks shipments from pickup to delivery, showing timelines, vendor actions, and exceptions in one place. For inbound shipping, this visibility is critical because most hidden costs happen before cargo reaches the port.

With tracking data, you can clearly see:

- Which vendors miss pickup deadlines

- Where shipments are delayed most often

- How long cargo sits in yards or ports

- Which routes generate extra fees

This information reveals weak points in the process. For example, if one vendor repeatedly delivers vehicles late to the port, causing missed sailings, the data makes that pattern obvious. Without tracking, the issue looks random. With data, it’s fixable.

Analyzing shipment data also helps eliminate unnecessary spending. Instead of paying storage or rebooking fees again and again, shippers can adjust schedules, change vendors, or enforce compliance rules. Small changes based on real data often lead to big savings.

For budget-conscious vehicle shippers, this matters because it protects against repeat mistakes. A low-cost vendor who creates frequent delays is no longer “cheap” once the data shows the full cost.

At YK Freight, shipment data is used to improve vendor performance, not just monitor it. By tracking trends and acting on them, vendors are pushed to meet standards, routes are optimized, and costs stay under control.

Why Can’t Most Vendors Optimize Shipping on Their Own?

Most vendors are experts in making or selling products, not in logistics. Shipping is usually a side task for them, not a core priority. This is one of the main reasons vendors often fail to choose the most cost-efficient delivery methods.

First, many suppliers lack logistics expertise. International shipping involves routing, port selection, documentation, compliance rules, and timing. Without a dedicated logistics team, vendors rely on familiar carriers or default options, even if those options are more expensive or inefficient.

Second, vendors often don’t have the right resources. Advanced tools like transportation management systems, performance analytics, or real-time tracking require investment. Smaller suppliers especially operate with limited staff and basic systems, which makes optimization difficult.

Third, and most important, vendors often lack motivation to reduce your shipping costs. Their goal is to ship the product and get paid. Whether the delivery method is the cheapest or the fastest for you is rarely their main concern. If delays or extra fees occur, the cost usually falls on the shipper — not the vendor.

For example, a supplier may choose a carrier that is convenient for them but arrives late to the port. The result is missed sailings, storage fees, and higher costs for the customer. From the vendor’s perspective, the job is done.

This is why relying on vendors alone for shipping decisions is risky, especially for budget-focused vehicle shippers. Without oversight, inefficiencies repeat and costs grow quietly.

That’s where structured vendor management and experienced partners like YK Freight make a difference. By controlling routing, setting performance rules, and tracking results, shipping decisions are optimized for cost and reliability, not vendor convenience.

How Does Partnering With a 3PL Improve Vendor Management?

Partnering with a third-party logistics provider (3PL) takes vendor management out of guesswork and turns it into a controlled process. For budget-conscious vehicle shippers, this often means fewer mistakes, lower costs, and fewer surprises.

A 3PL starts by assessing vendor performance. Instead of relying on promises, it looks at real data: on-time pickups, missed deadlines, damage reports, and extra fees. This makes it clear which vendors perform well and which ones quietly drive up costs.

Next comes cost control. A 3PL reviews routes, carriers, and timelines to find inefficiencies. Vendors often choose shipping options that are convenient for them, not cost-effective for you. A 3PL corrects this by selecting routes and schedules that reduce storage, rebooking, and handling fees.

A major benefit is streamlined inbound freight. The 3PL coordinates vendors, documentation, ports, and schedules in one system. This reduces miscommunication and prevents common problems like late arrivals or missing paperwork — issues that usually lead to extra charges.

For someone shipping a vehicle on a tight budget, this support matters. Instead of managing multiple vendors and chasing updates, you get:

Companies like YK Freight act as that control layer. They don’t just move cargo; they manage vendor behavior, enforce standards, and optimize decisions to protect your budget.

How Does Working With YK Freight Help Control Vendor-Related Costs?

Working with YK Freight means more than just booking a shipment — it’s about managing vendors effectively to keep costs under control. For budget-conscious vehicle shippers, every step in the supply chain can add unexpected expenses. YK Freight acts as a central coordinator, ensuring vendors perform reliably and efficiently.

First, YK Freight coordinates vendors at every stage of the process. From pickup to port handling, carriers, and documentation, all parties are managed under a single system. This reduces miscommunication, missed deadlines, and duplicate charges, which are common when vendors operate independently.

Second, YK Freight improves transparency. Customers can track their shipments in real time, see who is responsible for each step, and receive alerts about delays or issues. This level of visibility prevents surprise fees, such as storage or rebooking costs, because problems are spotted early and resolved quickly.

Third, YK Freight optimizes routing and scheduling. Vendors may default to familiar or convenient routes that are not cost-effective. YK Freight analyzes shipment data, evaluates alternatives, and selects the fastest, most affordable paths. This minimizes transit time, avoids congested ports, and keeps overall costs lower.

For example, a budget-focused customer shipping a vehicle internationally might face extra charges if a vendor misses a port cutoff. With YK Freight, the shipment is tracked continuously, and alternative solutions are implemented immediately — avoiding late fees and unnecessary expenses.

What Practical Vendor Management Mistakes Should Budget Shippers Avoid?

Even small mistakes in vendor management can quickly add up to big costs, especially for budget-conscious vehicle shippers. Understanding common pitfalls helps prevent unnecessary expenses and delivery headaches.

1. Chasing the lowest price only

It’s tempting to pick the cheapest vendor, but low rates often come with hidden costs. A budget-friendly quote may ignore handling inefficiencies, slower routes, or poor reliability. For example, a cheap carrier that frequently misses port deadlines can trigger storage fees, rebooking charges, or delays that end up costing far more than a slightly higher-priced but reliable vendor.

2. Ignoring vendor performance history

Past performance is the best predictor of future results. Skipping this step means you risk repeating mistakes. Vendors who have caused delays, damages, or extra fees in the past are likely to do so again. Reviewing performance data, on-time delivery rates, and customer feedback helps you choose partners who consistently meet expectations.

3. Failing to document responsibilities

Assuming that everyone knows their role can lead to confusion. Who handles pickup? Who submits the customs paperwork? Who ensures timely port arrival? Without written agreements, misunderstandings arise, leading to extra fees, delays, or disputes. Proper documentation — like a vendor compliance program — clarifies responsibilities and protects your budget.

4. Overlooking data and tracking tools

Not using shipment tracking or ignoring TMS data prevents you from seeing weak points in the process. Delays or extra costs often go unnoticed until it’s too late. Budget-conscious shippers need visibility from pickup to final delivery to catch problems early and avoid unnecessary spending.

5. Not partnering with experienced logistics providers

Trying to manage multiple vendors on your own can be overwhelming. Without logistics expertise, it’s easy to miss cost-saving opportunities or make inefficient routing choices. Working with a partner like YK Freight helps streamline vendor management, optimize shipping routes, and avoid preventable expenses.

How Can Better Vendor Management Lead to Long-Term Savings?

Effective vendor management isn’t just about solving problems today — it’s about building a system that consistently reduces costs over time. For budget-conscious vehicle shippers, this approach can turn unpredictable freight expenses into manageable, predictable costs.

The first key factor is consistent vendor performance. When vendors reliably meet deadlines, follow handling standards, and communicate effectively, shipments move smoothly. Fewer delays mean fewer emergency rebookings, storage fees, and rushed shipments, all of which directly save money.

Second, clear rules and agreements, such as a vendor compliance program, set expectations from the start. Vendors understand their responsibilities, penalties for mistakes, and required processes. This reduces misunderstandings, hidden fees, and disputes — keeping costs predictable and avoiding surprise expenses that can derail a shipping budget.

Third, expert coordination plays a major role. By partnering with experienced logistics providers like YK Freight, shippers can optimize routing, select the most efficient carriers, and manage multiple vendors effectively. Coordination ensures that shipments are planned strategically, problems are caught early, and savings opportunities — like consolidated shipments or alternative ports — are maximized.

Over time, these practices compound into long-term savings:

- Predictable shipping costs allow for accurate budgeting

- Fewer delays reduce additional charges and downtime

- Efficient coordination minimizes repeated errors and wasted resources

For someone shipping vehicles internationally on a tight budget, the difference is clear. Investing time and effort in better vendor management today prevents costly mistakes tomorrow, making every shipment more efficient and affordable.

Further Reading

What is Freight Management? A Simple Guide to Smarter Vehicle Shipping

Best Practices for Efficient Carrier Management | YK Freight Tips

3 Reasons to Use a 3PL for Your Retail Supply Chain

How a 3PL Can Help You Get Lower Freight Rates and Save on Shipping

ASK YOUR QUESTIONS